Orgasol® additives in transfer paper coatings improves print quality and image durability

The principal market for heat transfer paper is imaging on cotton and stretchable garments

Improved print quality, easy transferability, and enhanced image durability are the three most important benefits obtained by incorporating Orgasol® polyamide additives in coatings for transfer paper coatings.

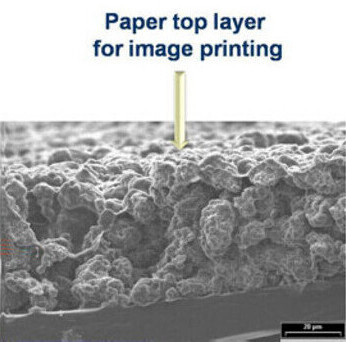

- Improved print quality – the spherical, micro-porous structure of Orgasol® products captures ink in its crevices. When the image is thermally transferred, the Orgasol® melts and releases the ink, resulting in improved print definition, depth of color, and overall print quality.

- Easy transferability – Orgasol® additives possess hydrophilic properties which makes them compatible with water based ink formulations. The relatively low melting points of the Orgasol® products designed for transfer paper applications makes image transferring easy because only a small amount of heat is required to melt the Orgasol® additive, which releases the ink captured in its crevices onto the substrate.

- Enhanced image durability – Orgasol® powders have good adhesion properties to the fabric because of the relatively high melt flow index of the Orgasol® additives. The high melt flow rate ensures optimal penetration of the Orgasol® powder into the textile fibers. This contributes to enhanced image durability, particularly as related to laundering resistance.

Orgasol® additive porous structure for ink absorption