Advanced Polymers for 3D Printing

Search materials by printing technology

Easy3D - Arkema 3D Printing Digital Platform

With the Easy3D digital platform, gain access to our team's powerful recommendations for advanced polymers for 3D printing. This tool supports your decision-making and part application development for on-demand manufacturing with a focus on the key processes of filament extrusion and powder bed fusion. Our platform ensures you select the ideal 3D polymers for your projects.

Sign up here

Discover Polymers for 3D Printing: Application Examples Across Industries

Consumer products and electronics

Consumer products and electronics

Our Advanced Bio-Circular (ABC) materials with flagship Rilsan® PA11 are the polymer of choice for powder bed fusion 3D printing. 100% bio-based Rilsan® PA11 provides excellent flexibility, as well as chemical and fatigue resistance often required in consumer products and electronics applications. With our materials, we enable the creation of impossible complex designs for consumer products and electronics. Explore recent applications of our 3D printing polymers, such as cosmetics packaging, eyewear, and electronic devices.

Check out the consumer products application examples

Industrial applications

Industrial applications

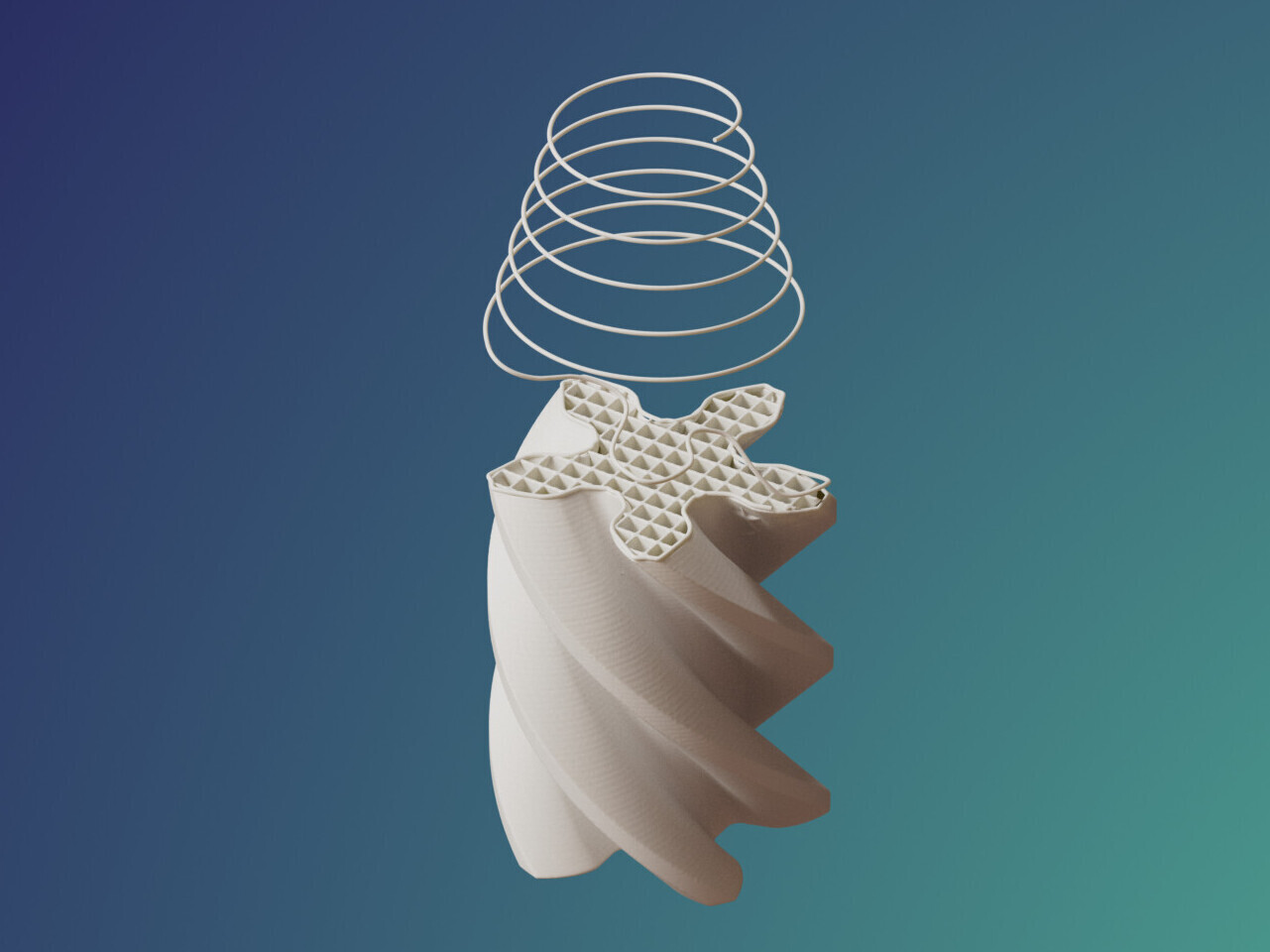

Healthcare applications

Healthcare applications

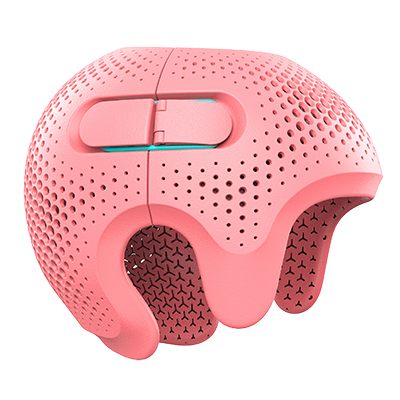

Rilsan® Polyamide 11 is the material of choice for medical device applications such as orthotics and prosthetics that require open customization. Thanks to the material's flexibility, 3D-printed devices for orthotics provide a high level of comfort to patients. Also, 3D printed devices with Rilsan® Polyamide 11 are resistant to impact, and chemicals related to sweating and are easy to clean. Therefore our customers choose 100% bio-based Rilsan® Polyamide 11 for application as ankle-foot orthosis, orthopedic insoles and cranial orthosis.

Check out the medical devices application examples

3D-printed objects in sports

3D-printed objects in sports

The sports industry is one of the early adopters of 3D printing technology and today we can find devices and accessories entirely or partially 3d printed with high-performance polymers. Our materials are adapted to creating complex but lightweight lattice shapes and custom-made pieces while guaranteeing the material performance of the 3D-printed pieces. From ski boots to golf clubs, our materials demonstrate the advantages of 3D printed polymers in sports applications.

Check out the sports application examples

Automotive & Transportation

Automotive & Transportation

Our high-performance polymers have always been at the heart of the continuing evolution in the automotive and transportation industry. Today with the disruptive additive manufacturing technologies and advanced polymers such as Rilsan® PA11. These materials enable faster production times and greater design freedom, with applications ranging from harness protectors to door-opening mechanisms, underscoring the transformative impact of 3D printing of polymers in automotive and transportation.

Check out the automotive and transportation applications

Find out more in the Resources section

![]()

Check out our latest case studies, white papers and articles prepared by our additive manufacturing experts.

Go to the 3D printing Resources

3D Printing Services: Enhancing Projects with Advanced Polymers for 3D Printing

Our team is dedicated to delivering exceptional service in every aspect of 3D printing. This commitment involves collaborating with partners to ensure comprehensive support in design, simulation, printing, and post-processing phases.

AON3D

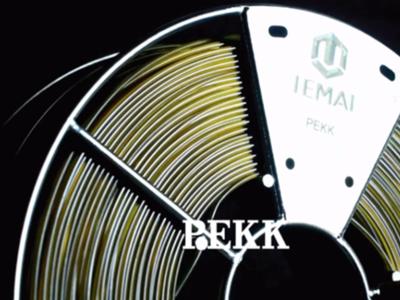

KIMYA PEKK-A filament, made from Arkema's Kepstan® PEKK, is a PAEK family material with exceptional mechanical, thermal, and chemical resistance properties. Kepstan® PEKK is optimized for easier 3D printing and better interlayer adhesion. In this timelapse, a Kepstan® PEKK fluid mixer was printed on the AON M2 with a section cut out to see the inner workings, showcasing the advanced capabilities of 3D polymers in fabricating complex and durable components.

Founded in 2015 by a team of materials engineers, AON3D is a Montreal-based additive manufacturing hardware, software, and material science company. AON3D’s large high-temperature AON M2+ industrial 3D printer with Arkema Kepstan® PEKK enabling engineers and designers to create parts with advanced 3D polymers that possess exceptional mechanical and thermal properties, meeting the demands of various applications.

Materialise

Watch our joint webinar entitled "Empowering Sustainability in Eyewear: The Story behind Bio-Based PA 11 Material with Arkema," highlighting the role of sustainable 3D polymers in revolutionizing eyewear manufacturing. Learn about the seamless integration of performance and environmental responsibility with bio-based polymers for 3D printing. Also, watch Materialise's short promo video showing the beautiful Rilsan® PA11 eyewear frames they've brought to life through 3D printing.

Learn more about Rilsan® PA11

Lynxter

Lynxter, an innovator in the French additive manufacturing industry since 2016, specializes in developing machine tools for Industry 4.0 with a focus on 3D printing of polymers. The R&D team from Lynxter worked on improving the mass of a cast aluminum intake manifold. In order to optimize the weight of this engine assembly, the teams had to rethink its design and composition and make the choice to print it in PEKK. By employing Kepstan® PEKK in its amorphous form (PEKK-A), they harnessed the unparalleled mechanical and temperature resistance of advanced 3D polymers, showcasing the critical role of polymers for 3D printing in modern engineering solutions.