Advanced Bio-Circular Materials Specified by World's Leading Sports Brands

A Complete Offer for More Sustainable Footwear

1. Solutions for Upper Applications

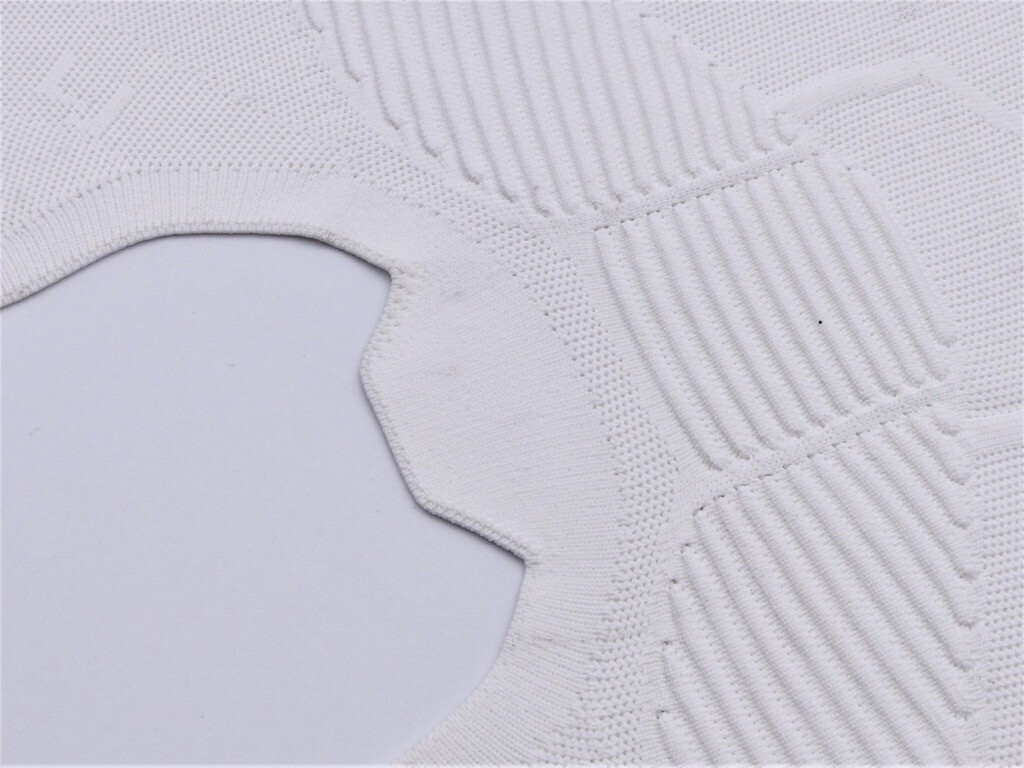

More sustainable running shoes require more sustainable uppers, while keeping high durability and comfort. Rilsan® PA11 yarns are an ideal choice for upper applications as they provide fast-drying, low deformation and abrasion resistance while being 100% bio-based, derived from renewable castor beans.

We work with partners specialized in fiber and upper manufacturing, contact our team for more information.

Platamid® low melt temperature adhesives for thermoforming uppers are also available in the Platamid® product range. In the form of fusible filaments (yarn), Platamid® resins can bring the 3D shape to footwear and maintain it over time.

Learn more about Platamid® hot melt adhesives.

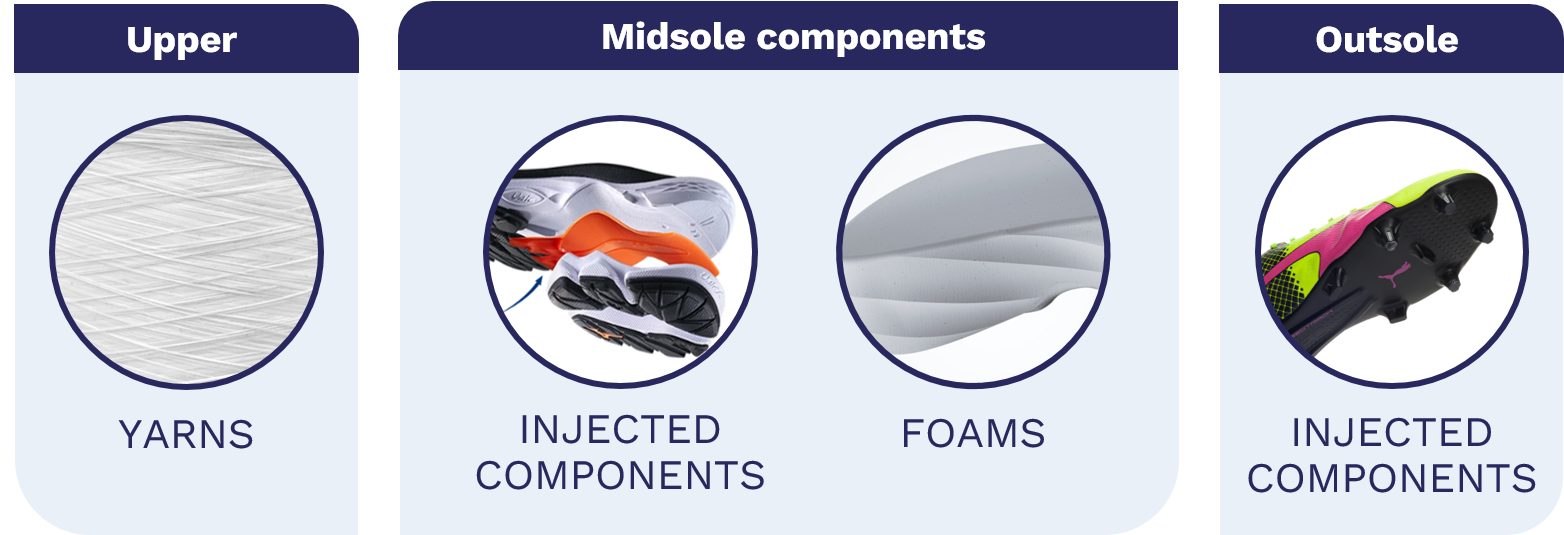

2. Solutions for Midsole Components

INJECTED COMPONENTS

There are many parts of a running shoe that can be enhanced with Pebax® elastomers. Midsole components like torsion bars and propulsion plates, along with other components like heel counters are great applications for Pebax® materials. These lightweight polymers provide high energy return that world champion runners recognize. A wide range from soft and flexible to hard and rigid grades makes for a wide spectrum of uses.

REINFORCED GRADES FOR ADDED PERFORMANCE

For even more structure and snapback properties, glass and carbon fiber filled Pebax® and Rilsan® components can be incorporated into foam midsoles. This combination allows for comfortable, lightweight constructions to produce high energy return.

ULTRA LIGHT & RESPONSIVE FOAMS

New performance foams have taken the world of running by storm recently but there is only one type of foams that outperforms all the others: Pebax® foams.

To allow even more lightweight designs, Pebax® foams can be used for midsoles and add significant flexibility and fatigue resistance, while maintaining an ultra responsive feeling and low compression set. Some of the most prestigious sports brands are using this technology today.

Contact our team for more information.

FOCUS ON: HANDBALL & BASKETBALL SHOES

The Pebax® technology not only powers running shoes but also applies for a wide selection of sports!

3. Solutions for Outsole Applications

Outsole plates are used widely for cleated footwear. The lightweight rigidity and high energy return of Pebax® TPE is the reason why many professional athletes choose Pebax Powered® cleats. Where extreme rigidity is required like baseball, football, and soccer cleats, glass fiber and carbon fiber (for reduced weight) filled grades are available. For added design flexibility, transparent Pebax® Clear grades are also available.

ROSS FLEX TEST

For cleated footwear especially, the Ross Flex test is an important indicator for long-lasting, high performance cleats. Pebax® and Rilsan® grades can endure more than 50,000 cycles, even at cold temperatures (-40ºC) and up to a 90º bend angle without breaking.

Unrivaled Performance: Comparison with TPU

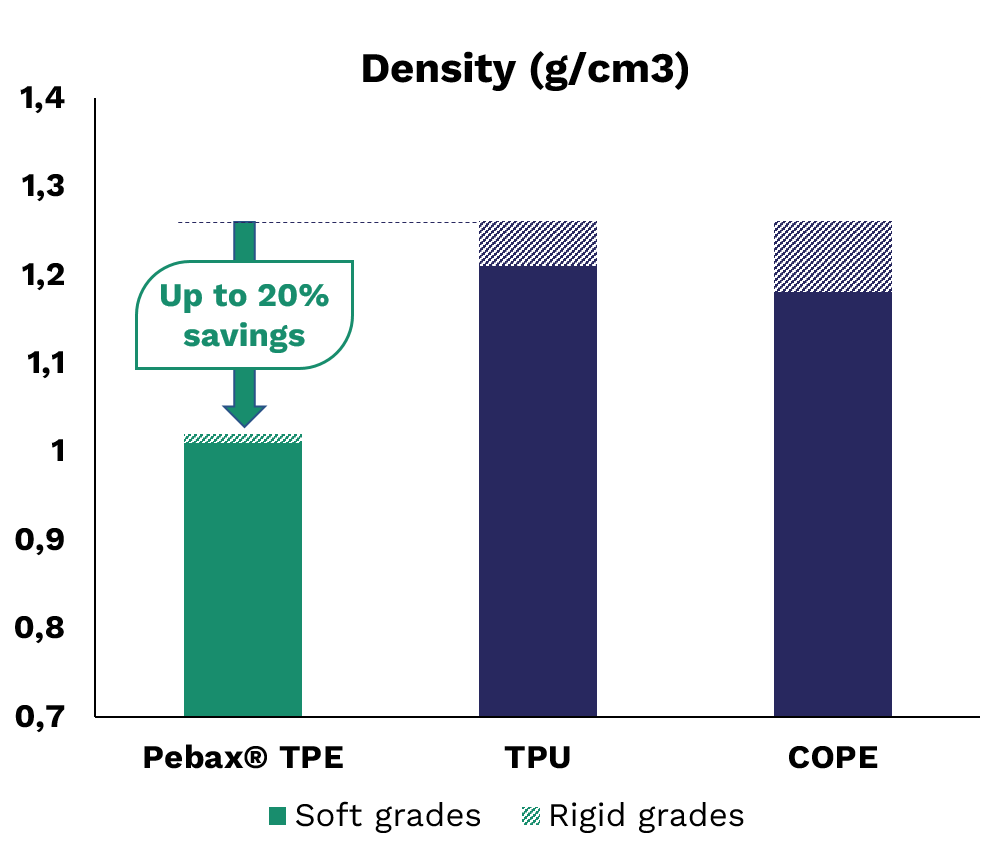

Lightweight

Solutions from the Pebax® family offer extreme lightweight performance. Compared to alternatives like TPU and COPE these solutions can be up to 20% lighter. The strong mechanical properties of Pebax® elastomers can also allow for thinner designs, reducing even more weight and costs.

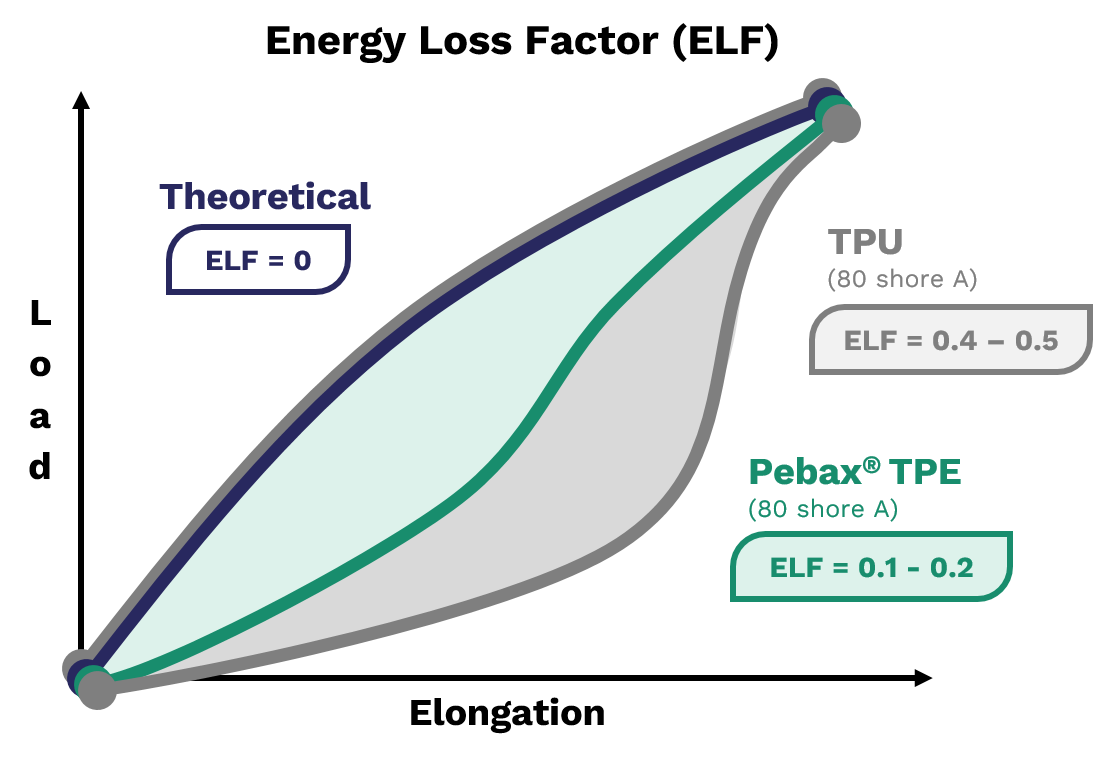

Energy Return

Yes, there is science to support it! Pebax® elastomers exhibit a lower energy loss factor when relaxed after being stressed compared to TPU. This means athletes with a shoe or cleat with Pebax® TPE in it will get more out of every step.

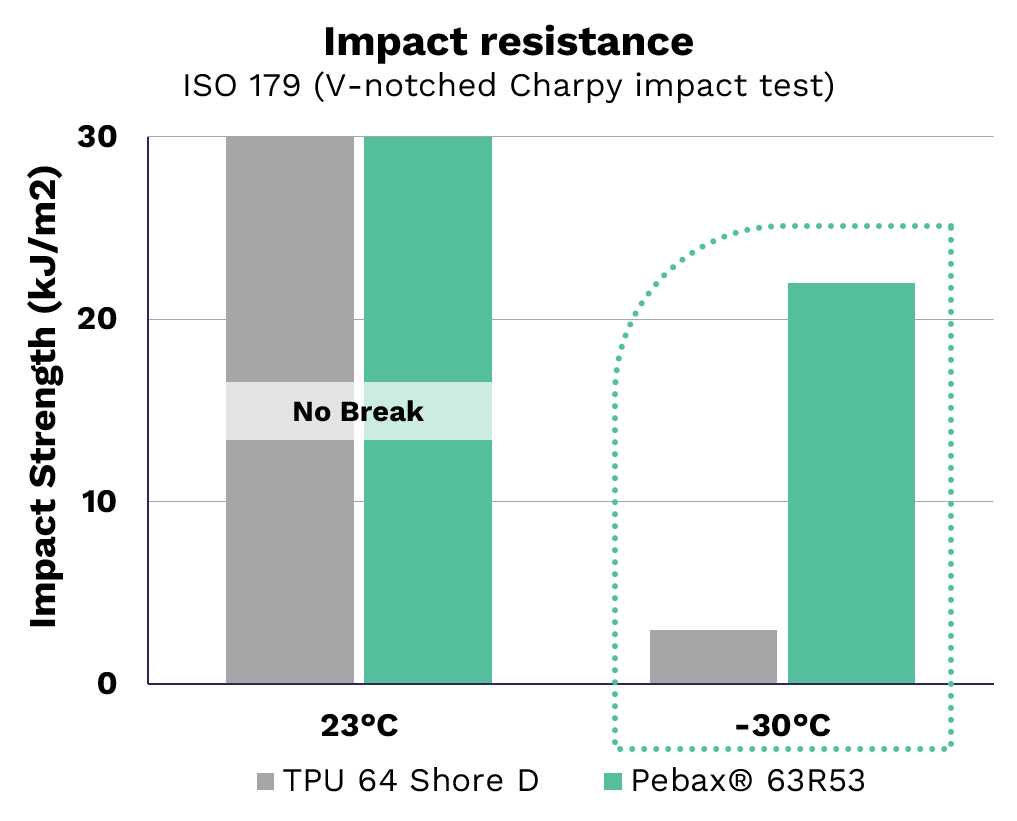

Durability

Shock resistance, enduring elasticity, toughness, and flexibility are important for any sports application. Long-lasting Pebax® solutions maintain these properties in cold and hot conditions, so no matter what the season, athletes can rely on consistent performance from their equipment.