Sustainable Solutions for Winter Sports Equipment

Ski Boots

Pebax® elastomers are the material of choice by some of the most recognized ski boot manufacturers. The Pebax® family consists of grades with varying flexibility and hardness levels. The wide range allows for exceptional solutions for alpine, cross-country, and touring (freeride) skiing styles.

Pebax® Rnew® grades are derived partially from the castor plant, being up to 97% bio-based and are a preferred solution for high performance boots with reduced environmental footprint.

Ski Top Layer / Top Sheet

Rilsan® PA11 and Rilsamid® PA12 are both excellent choices for use as protective ski top layers, which is why these resins have been used for over 20 years. Both of these resins process into films easily and make for simple sublimation printing. A high level of transparency also makes for beautiful finished graphics.

However, Rilsan® PA11 exhibits improved scratch resistance and mechanical properties compared to PA12, so for high-end models, manufacturers should opt for PA11.

Rilsan® PA11 also has the benefit of being biobased, 100% derived from the castor plant.

We are in contact with world's leaders in top layer manufacturing, contact us about your product development!

Unrivaled Performance: Comparison with TPU

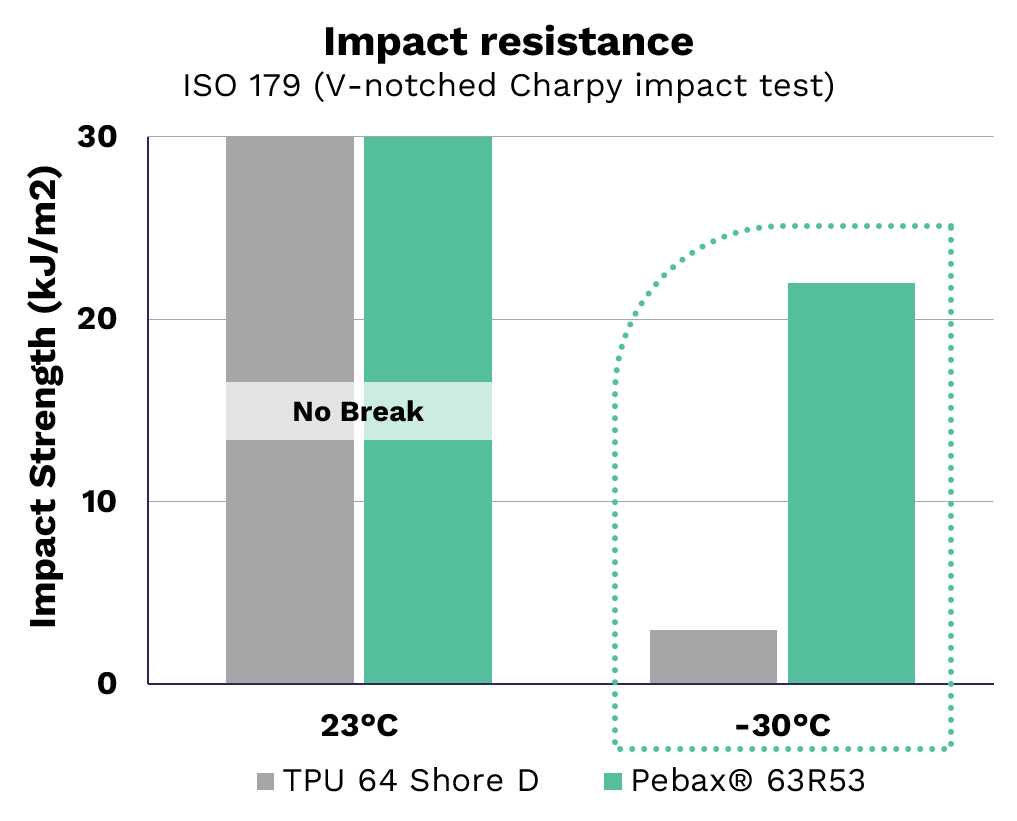

Shock Resistance & Durability at Cold

Low temperature impact performance is essential for manufacturing a durable ski boot. Pebax® elastomers and Rilsan® PA11 have exceptional cold impact performance making them durable solutions for ski boots. Rilsan® PA11 polyamides also have excellent scratch and UV resistance, making them a great solution for protective ski top layers.

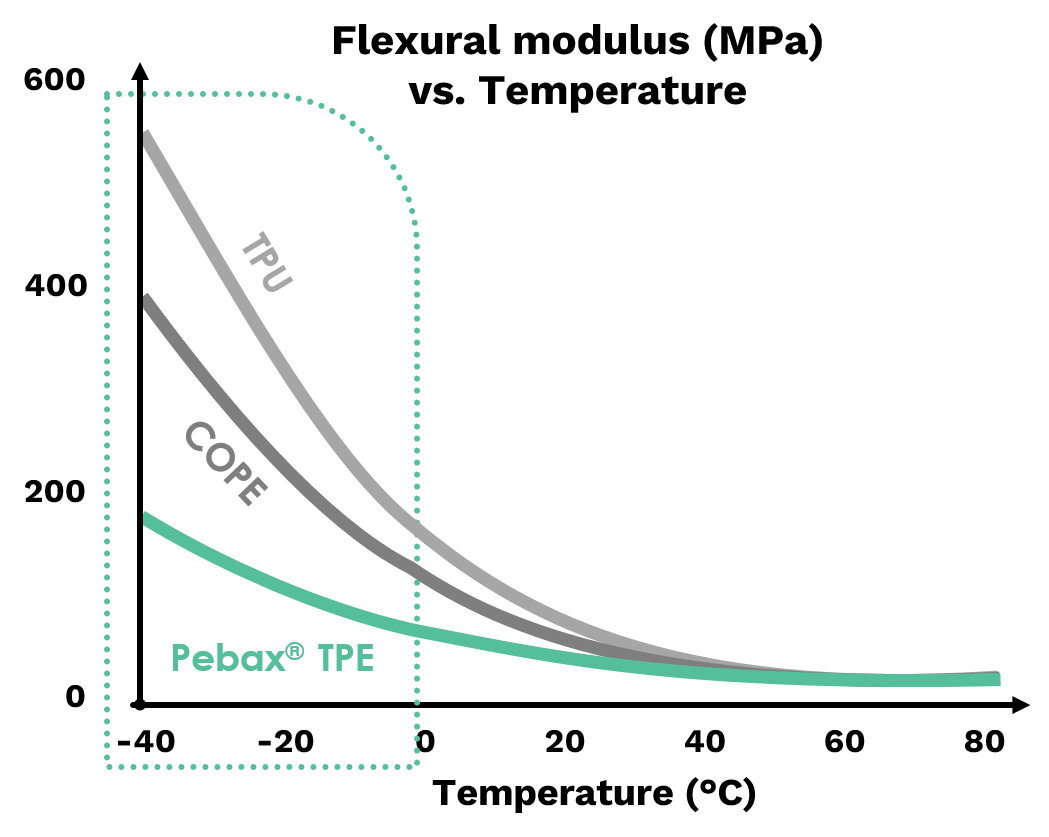

Flexibility & Comfort at Cold

Boots can be a skiers best friend or worst enemy. Crafting a boot that maintains flexibility and comfort even at extremely low temperatures can make a huge difference for skiers. Pebax® elastomers outperform TPU, COPE, and other alternatives when it comes to cold stiffening, which makes for a more resilient and comfortable ski boot. Rilsan® PA11 polyamide ski top layers also maintain flexibility at low temperature and have the process flexibility to make sublimation printing (and other decoration technology) hassle-free.

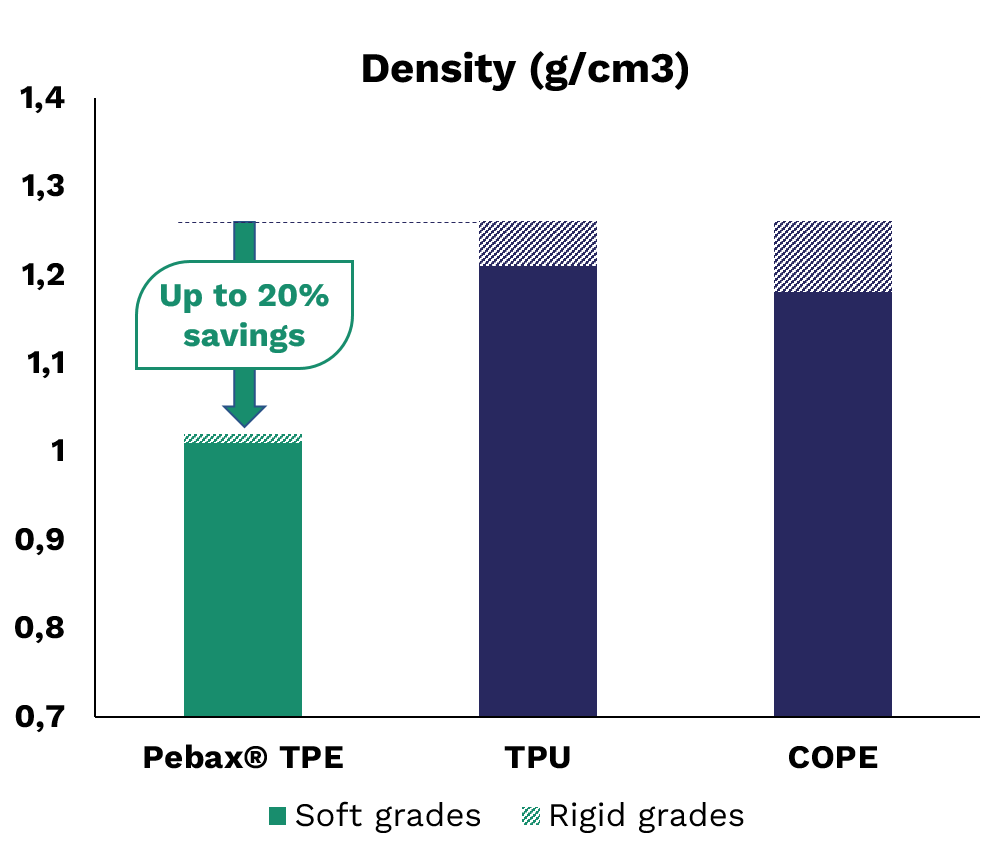

Lightweight

The sheer amount of plastic used in ski boots today only magnifies the importance of choosing a lightweight polymer when designing high-end equipment. Both Pebax® elastomers and Rilsan® PA11 polyamides have lower densities (up to 20%) than TPU and COPE alternatives. This is especially important for touring (freeride) boots where the ski trip often involves a long hike.