Rilsan® PA11 Fine Powders

A 100% biobased polymer for powder coating

The Rilsan® Fine Powders product range is based on polyamide 11, a 100% biobased polymer. This high-performance polymer originates from the renewable castor plant, which does not compete with animal or human nutrition. We at Arkema developed a range of Advanced Bio Circular solutions with their trademark properties, such as light weight, flexibility, durability, energy return, and overall toughness.

Learn more about Advanced Bio Circular materials

Find the right product grade

Discover our material database and search for Rilsan® PA11 Fine Powders' product grades for your project. Take advantage of the material comparison feature and compare the product properties. The technical datasheets for each product are available for download.

Find your powder coating applicator

At Arkema, we continuously work to develop a global network of powder-coating applicator partners. We value applicator-partners expertise in powder coating technology and understanding of customers' needs in terms of powder coating's performances, effects and colors.

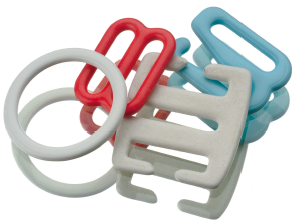

Color-matched formulations for powder coating

These powders are available in many different particle size distributions and formulations to allow application by common powder coating methods used today. A wide variety of colors are available through dry blend or melt-mix coloration. The melt-mix (mass coloration) process produces a stable finish and superior UV stability compared to dry blended grades. Special grades and color-matched formulations can be developed specifically to suit customer needs.

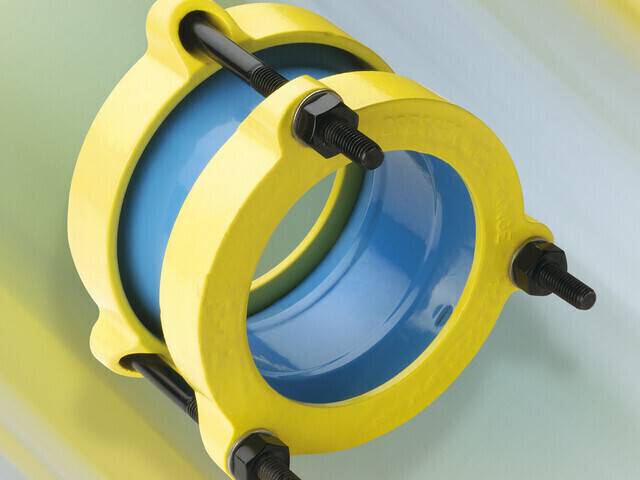

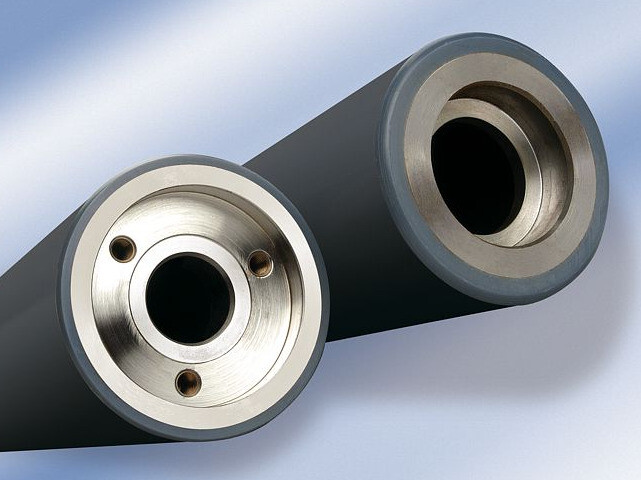

Rilsan® Fine Powder Coatings' Physical and Chemical Properties

The main advantages Rilsan® Fine Powder coatings offer are abrasion resistance, toughness and impact resistance, chemical and corrosion resistance, weather resistance, and easy processing. The chemical resistance of Rilsan® PA11 coatings is reflected both in high dimensional stability under harsh conditions and in the non-degradation of the polymer matrix, making it a great solution for highly demanding applications. To find out more about Rilsan® Fine Powders' physical and chemical properties for highly demanding applications, you can download specific brochures.

download the brochure for physical properties

Rilsan® Fine Powders Application Processing

Our team provide you with a detailed guide about processing methods to apply Rilsan® Fine Powders to obtain the most efficient application result. Depending on your application, you can use Fluidized bed dipping coating, Electrostatic Spray coating or minicoat/maxicoat process for application to a large number of small articles. Visit our page for the processing guide for more details.

Go to the processing page

Literature on Rilsan® Fine Powders

To help you learn more about Rilsan® Fine Powders' properties we provide complementary information in our literature page. You can download brochures from our selected library of brochures on various processing technologies and applications.