Sustainable Solutions For Surgical Tools And Metal Replacement

Arkema offers a wide range of medical grade resins for various healthcare applications.

Discover how our Advanced Bio-Circular Medical polymer can fit your needs with Amelie, Business Development Engineer for Healthcare.

DOWNLOAD THE RILSAN® FKZM 65 O TD MED BROCHURE

Explore more information on specific applications by navigating through the tabs.

Did not find what you were looking for? Please reach out to us through the contact form and we will get back to you!

CASE STUDY - REPLACEMENT OF PARA BY SURGICAL DYNAMICS

REPLACEMENT OF PARA

Rilsan® MED polyamide 11 was easier to process compared to PARA with lower mold temperatures and injection pressure which leads to a significant decrease of cycle times while maintaining component integrity.

Being bio-based, it answers the increasing needs of end-customers looking to source sustainable products.

When replacing metal, material selection is of the utmost importance to achieve optimal performance.

Medical device producers are looking for polymers that are:

- Biocompatible

- Sterilizable and resistant to chemical agents

- Easy to process

- Colorable and allowing for a perfect finish

- As high performing as metal

Our new 65% glass filled Rilsan® MED offers such properties and is a perfect fit for those demanding applications.

Why replace metal with polymers?

Improve the comfort of your hand-held medical tools

- Lighter weight - Being lighter, medical devices made of polymers improve the user’s experience through increased comfort and reduced fatigue.

- Improved ergonomics - Being moldable, engineers can design comfort features into the part for optimal ergonomic designs.

- Warm to the touch – Plastic handles and components are warm to the touch; metals tend to be cold.

- Electrically insulated – No need to coat your electro-surgical device handles; polymers are inherently insulating.

Reduce the cost of your device

- Using polymers is a good way to reduce the cost of raw materials

- Once molds are approved, polymers offer

- Ease of processing

- Shorter manufacturing times

- Improved production yield

- Opportunities for improved process efficiency vs. metals

An Advanced Bio Circular polymer for sustainable tools or metal replacement

Downsides of traditional polymers used to replace metal in surgical tools

Traditional oil-based polymers are a challenge for single-use surgical tool applications. They are not aligned with sustainability megatrends and are not aligned with most companies’ commitments.

Rilsan® MED polyamide 11 – From castor bean to advanced materials, a miracle of modern science

Rilsan® MED polyamide 11 is derived from the castor plant. The castor plant grows where nothing else can grow i.e it does not compete with food and does not cause deforestation. It is also a highly profitable crop for the farmers.

Main Properties of Rilsan® MED PA11 Grade for Surgical Tools and Metal Replacement

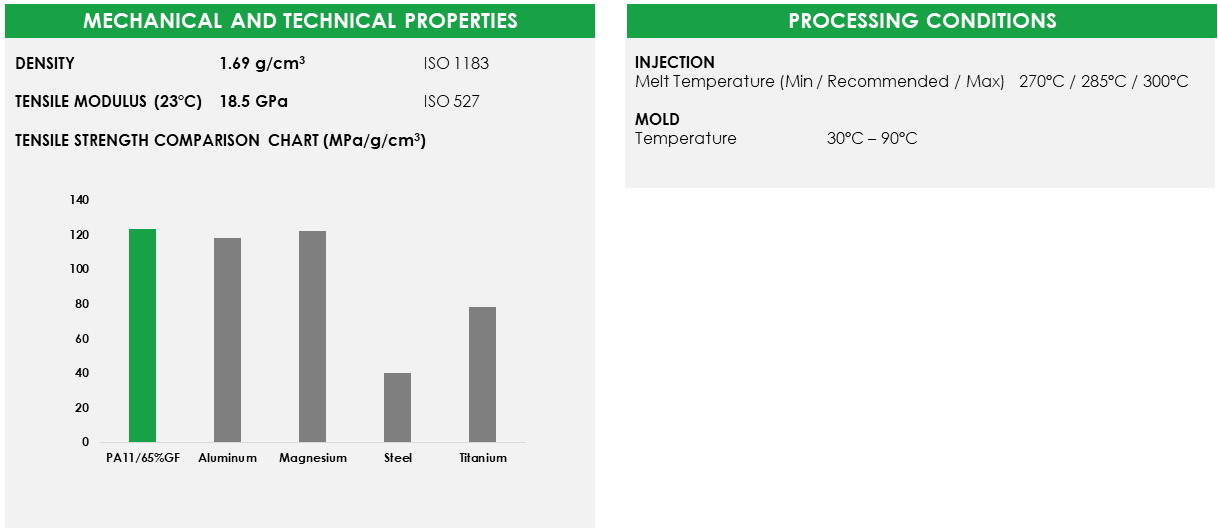

Mechanical and Technical Properties

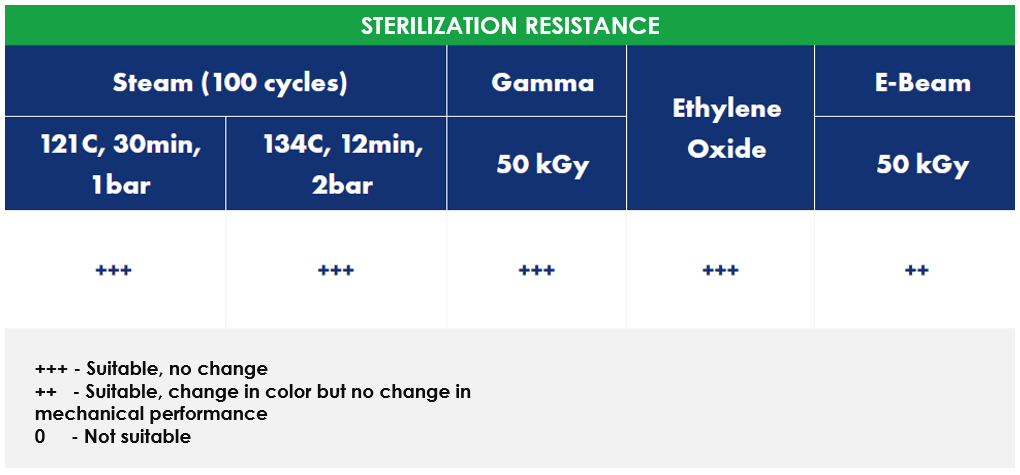

Sterilization Resistance

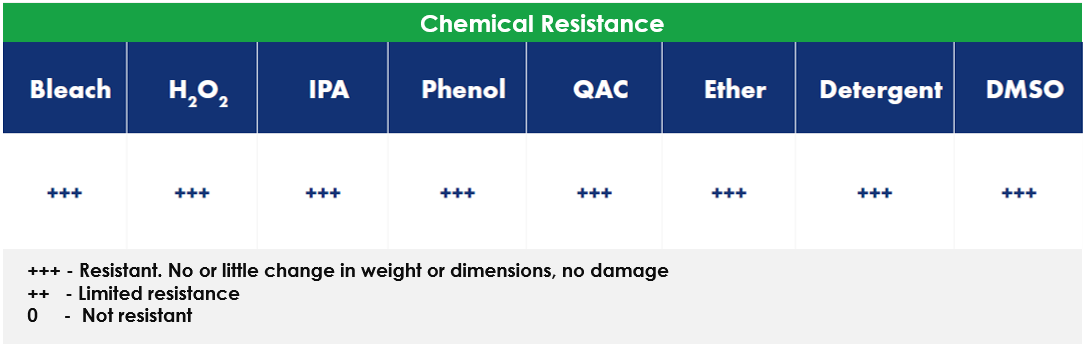

Chemical Resistance

Bio-compatibility

The 65% glass filled Rilsan® MED Polyamide 11 passed:

- USP Class VI standard

- ISO 10993-4 Hemocompatibility

- ISO 10993-5 Cytotoxicity

- ISO 10993-10 Skin sensitization

Compliance letters available on request.

Life Cycle Analysis

>98% bio-based carbons (according to ASTM 6866). Full life cycle analysis available on request.

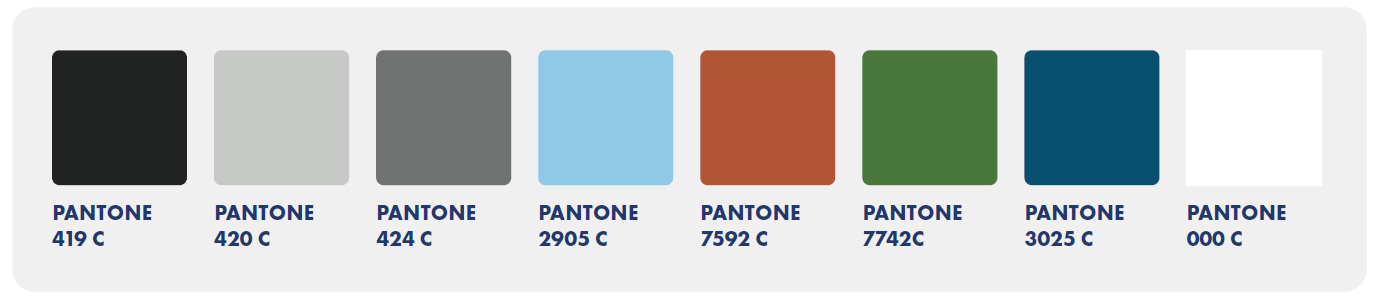

Colors

Color masterbatches are available in 8 shades developed by our partner Foster Corporation. All colors have been formulated using pigments that have passed biocompatibility testing. Foster Corporation offers color matching service on demand.

Recyclability

The new 65% glass filled Rilsan® MED polyamide 11 is bio-based and fully recyclable.