Kynar® PVDF Resin

Welding Guidelines

WELDING PARAMETERS

In order to produce a high quality weld, three parameters must be controlled:

- Temperature: within a specified range in order to produce the proper melting of the resin.

- Pressure: excessive pressure must be avoided to avoid forcing the melted resin out of the weld interface.

- Time: to provide uniform heating throughout the weld zone as the material’s low thermal conductivity slows the heat transfer.

After reaching the proper melt conditions, slow cooling is necessary to reduce stress and permit the intermolecular diffusion of the polymer. Testing of welds for physical characteristics such as tensile, bend angle, etc. within 12 hours after completion of the weld will produce erroneous results. The weld zone should be allowed to cool to ambient temperature prior to the next weld pass. If the weld zone is not allowed to cool, excessive stress will result, which may cause distortion of the weld. In order to produce the highest quality weld, the surfaces to be welded must be clean. The surface should be scraped just prior to every weld pass. Wiping with a solvent only spreads the contamination

Welding Methods used with Kynar® PVDF Resin

Several methods of fusion welding Kynar® PVDF components are possible. The most common and successful approaches to welding Kynar® PVDF components are heat contact and hot gas welding using a welding rod. Ultrasonic, hot lamination, infrared (IR), electrofusion, resistance heating, spin and radio frequency welding are all methods suitable for bonding Kynar® resin to itself.

Hot Gas Welding of Kynar® PVDF Resin

The welding of Kynar® PVDF can be performed using conventional hot gas welding equipment. It is highly recommended that automatic temperature welding equipment be utilized. This type of equipment greatly reduces the possibility of substandard welds due to temperature variations during the welding process. A suitable weld can be defined as one capable of meeting the Deutscher Verbena Fur Schweissen Und Verwandte Verfahren E.V. (DVS) requirements for welder certification. The values in the table below are the current conditions accepted by the DVS as the optimal welding perimeters.

The welding area should be well ventilated so that heat and fumes generated during the welding process are drawn away from the welder. Drafts, excessive air movement and similar conditions that would cause the weld to cool rapidly must be avoided. The weld area must be clean and free of particles that will be attracted to the weld.

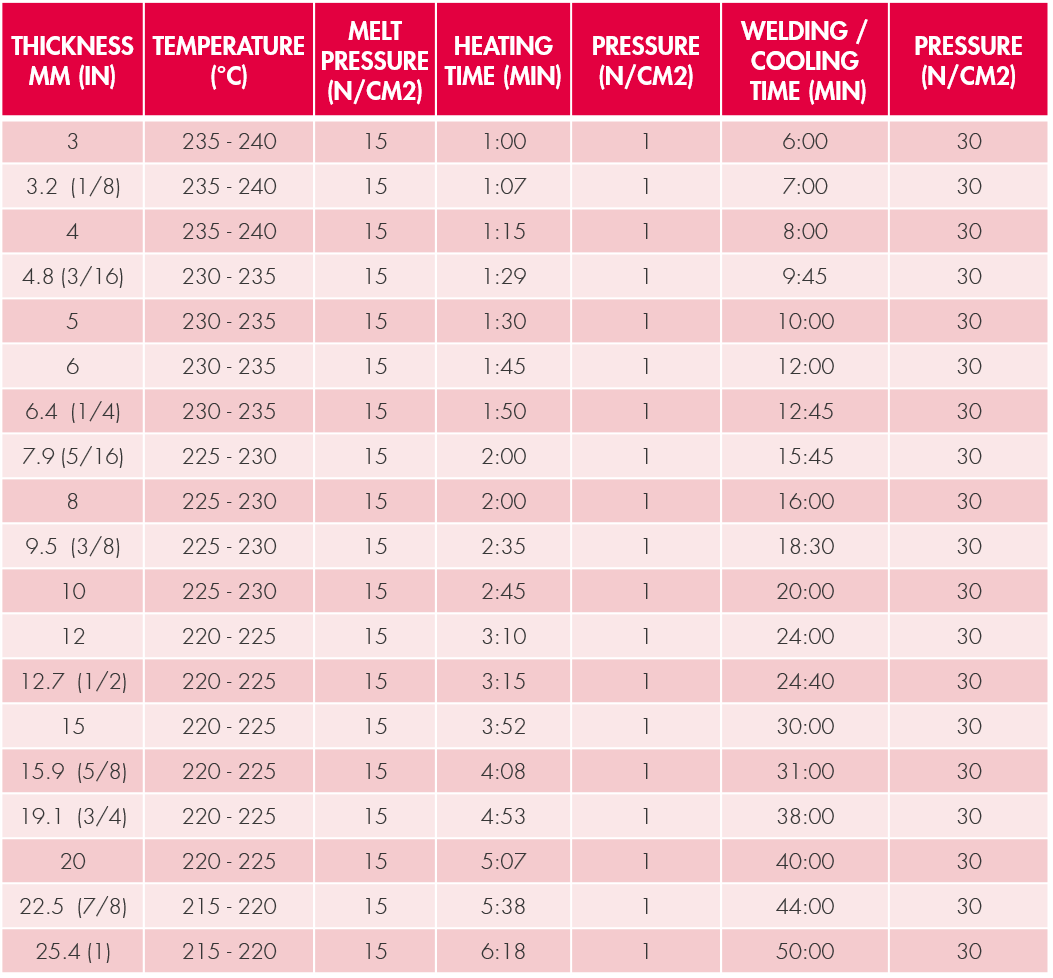

Hot Gas Welding Conditions as per DVS

**Force applied to weld zone through welding gun.

Butt Welding of Kynar® PVDF Resin

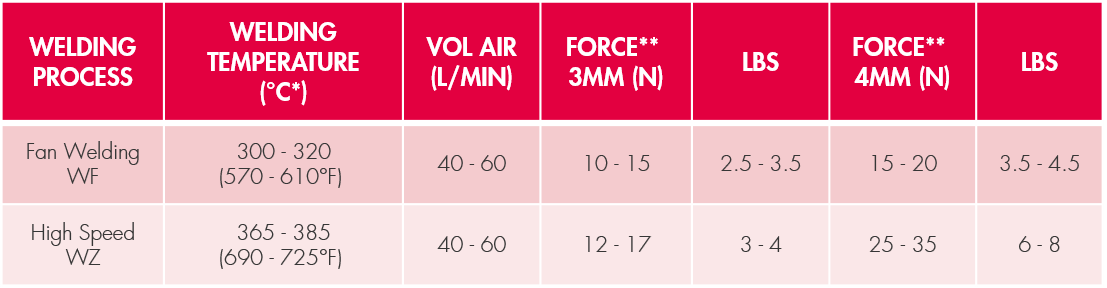

The conditions listed in the table below are recommended starting points for the welding of Kynar® PVDF slab.

Optimal conditions may vary slightly from these conditions. The welding/cooling times are the suggested times for welding rolled sheets. Flat sheets may be removed sooner because they will not tend to distort if kept flat until cool.

Recommended Welding Conditions for Butt Welding* Kynar® PVDF Resin