Kepstan® PEKK resins

for Injection Molding and Extrusion

Kepstan® PEKK is a versatile material that can be used in many traditional thermoplastic processes such as injection molding and extrusion. The material properties offer ultra-high performance for the most extreme environments, including high temperature and demanding mechanical requirements.

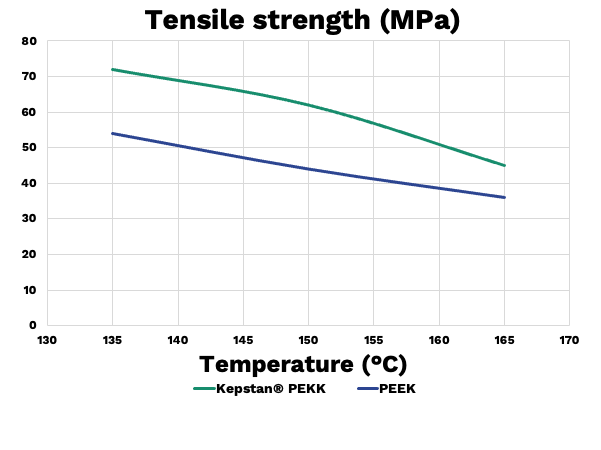

Kepstan® PEKK maintains its high tensile strength at elevated temperatures over 150°C.

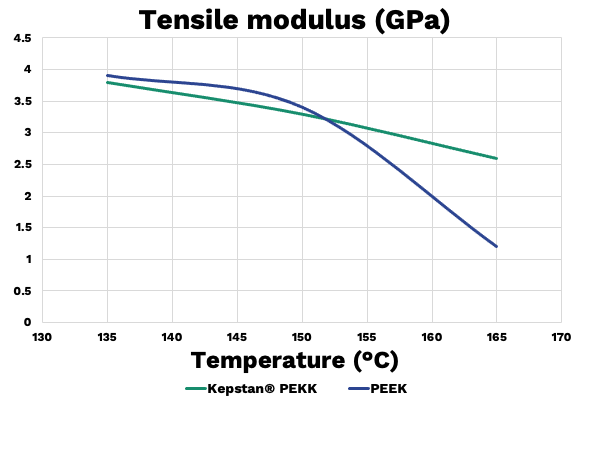

Kepstan® PEKK retains a high tensile modulus at extreme temperatures up to 165°C.

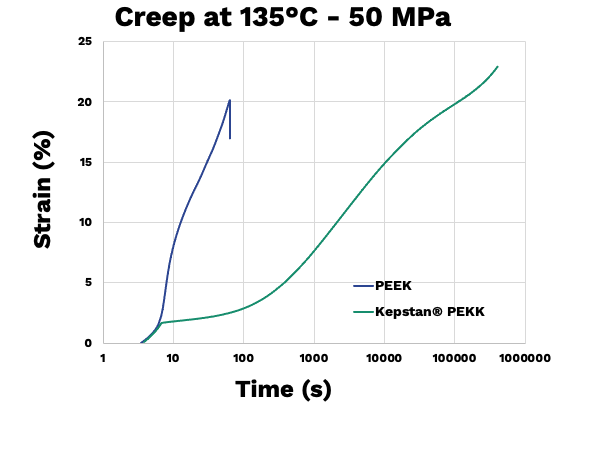

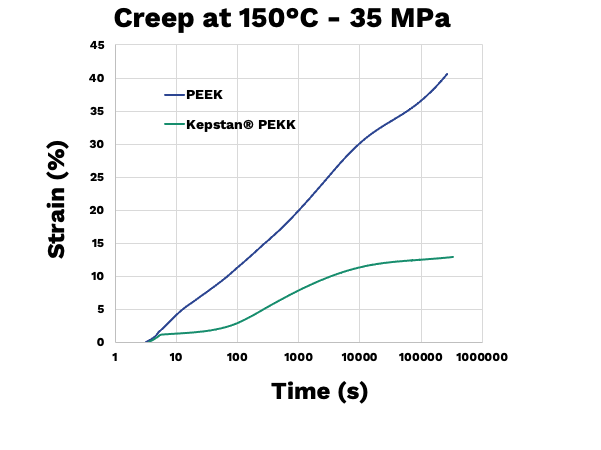

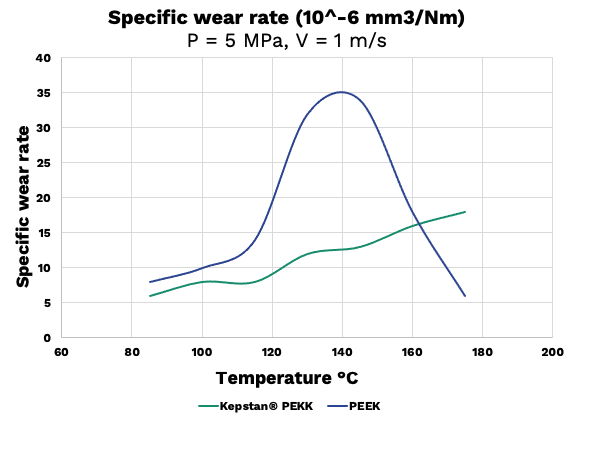

Kepstan® PEKK exhibits a regular and controlled wear rate even at high temperatures and above its Tg (165°C).

Compatible with Traditional Processing Methods

Stock Shapes Extrusion:

- Long residence time and pressure leads to high crystallinity

- Can be machined into gears, seals, and complex geometries

Compression Molding:

- High crystallinity process

- Quick turn-around for manufacturing

- Can be done from Kepstan® PEKK pellets

Injection Molding:

- Fast manufacturing for higher volume production

- Good crystallization - retains excellent properties