Kynar® PVDF Resin

Physical & Mechanical Properties

GENERAL PHYSICAL & MECHANICAL PROPERTIES

Kynar® PVDF and Kynar Flex® resin grades give the design professional the option to select either rigid or flexible materials when processing. As a material of construction for pumps and pipe, Kynar® resins exhibit excellent resistance to abrasion. Kynar® PVDF can also be manufactured into thin, flexible and transparent films, filament, and tubing. Sunlight has little effect on Kynar® resins. For information on the ability of Kynar® PVDF to withstand ultraviolet radiation, please contact an Arkema Fluoropolymer Representative. The tabs below titled "Kynar® Copolymer Series" and "Kynar® Homopolymer Series" list typical properties of Kynar® and Kynar Flex® fluoropolymer resin grades, which display excellent flexural and tensile creep properties.

STRENGTH & TOUGHNESS

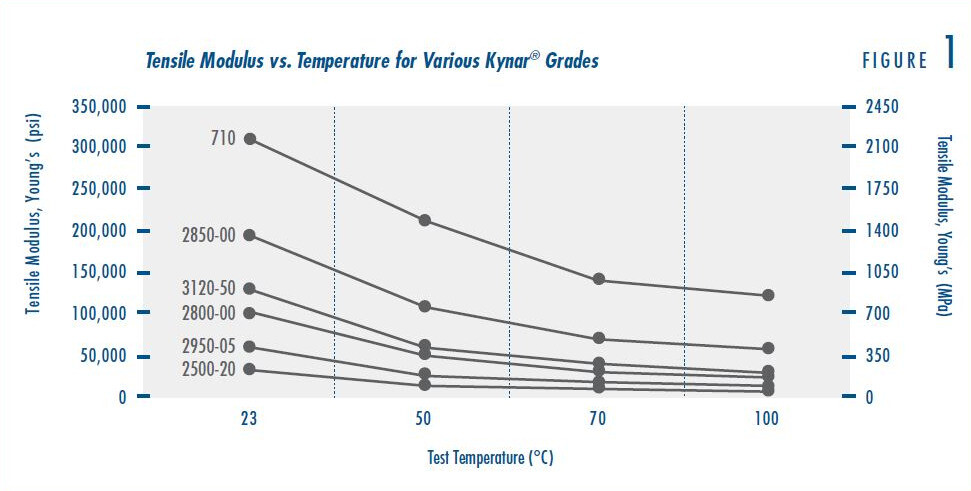

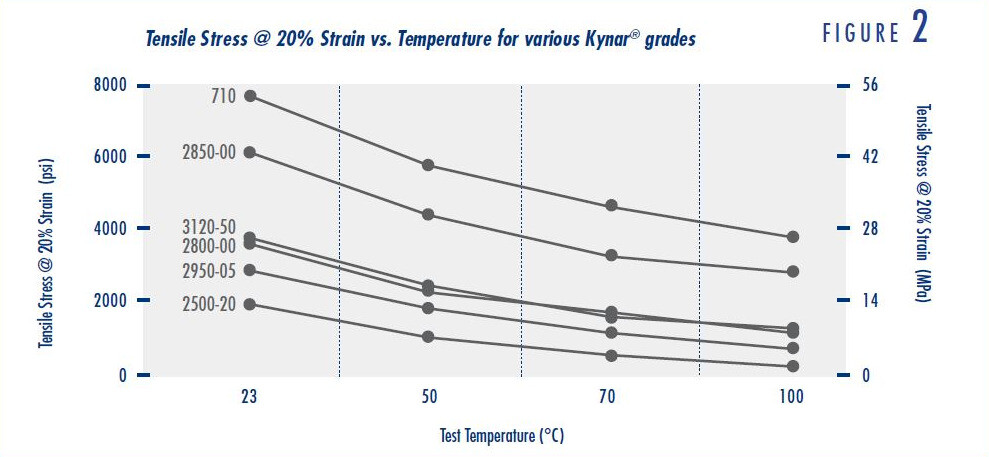

Kynar® and Kynar Flex® PVDF fluoropolymers are inherently strong and tough as reflected by their tensile properties and impact strength. An ambient temperature tensile strength at yield of 35-55 MPa (5,000-8,000 psi) and an un-notched impact strength of ‘no break’ offered by select resins demonstrates this. These characteristics are retained over a wide range of temperatures, as shown in Figures 1 and 2 below.

Figure 1: Tensile Modulus vs. Temperature for Various Kynar® Grades

Figure 2: Tensile Strength at 20% Strain vs. Temperature for Various Kynar® Grades

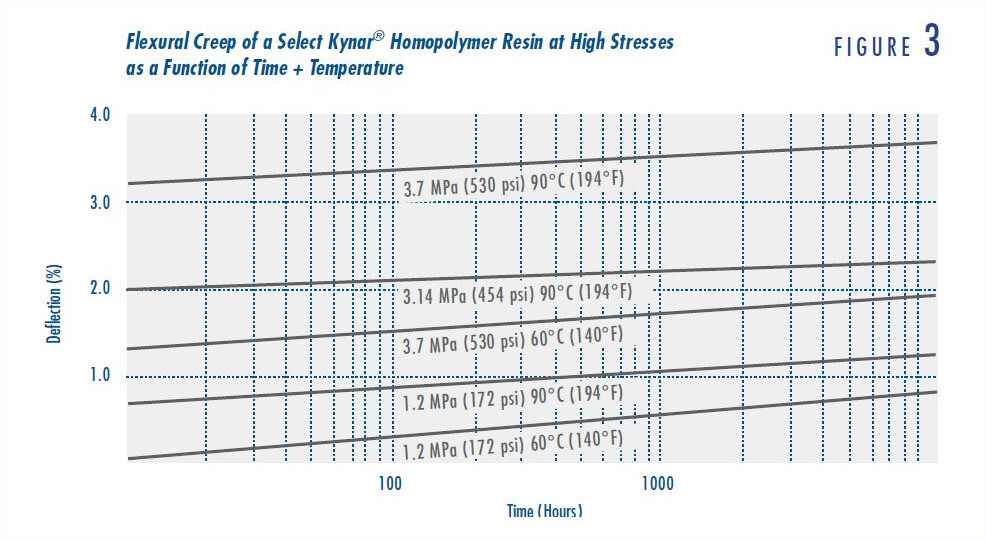

FLEXURAL CREEP

Compared to many thermoplastics and fluoropolymers, tensile yield of 15-55 MPa (2,200-8,000 psi), Kynar® fluoropolymers have excellent resistance to tensile creep and fatigue. The long-term resistance of Kynar® resins to flexural creep at elevated temperatures is shown in Figure 3, which illustrates that Kynar® resins are suitable for many applications where load bearing characteristics are important. Likewise, the short-term flexural creep resistance of Kynar® homopolymer resins reflects superior load bearing performance.

Figure 3: Flexural Creep of a select Kynar® Homopolymer Resin at High Stresses as a Function of Time and Temperature

THERMAL PROPERTIES

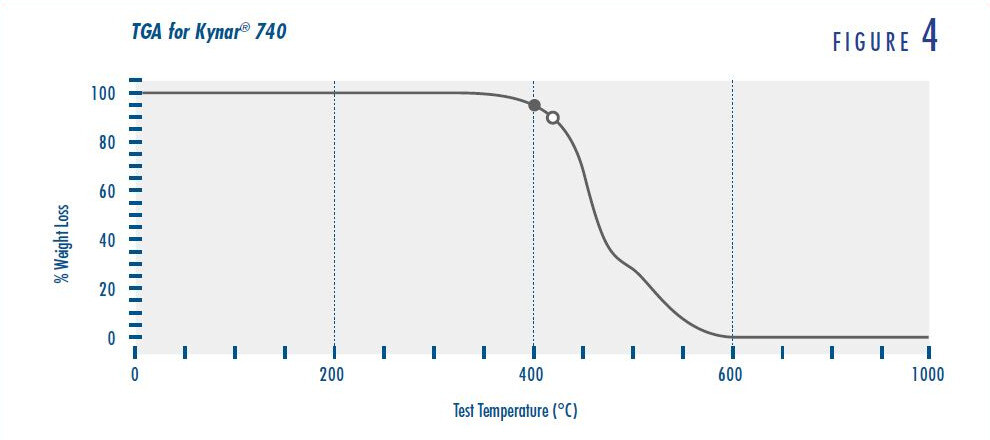

Kynar® resins exhibit high thermal stability, as illustrated in tabs "Kynar® Homopolymer Series" and "Kynar® Copolymer Series" below. Prolonged exposure of Kynar® resin at 250°C (482°F) in air does not lead to weight loss. No oxidative or thermal degradation has been detected during continuous exposure of Kynar® resins to 150°C (302°F) for a period of ten years. In testing, select Kynar® resins have been given an RTI of 150°C. As thermogravimetric analysis (TGA) thermograms indicate in Figure 4, Kynar® homopolymer resins are thermally stable up to 375°C (707°F) when heated in air at the rate of 5°C/min (9°F/min). Kynar® resins thermally decompose at temperatures greater than 375°C (707°F). (Please review Kynar® Material Safety Data Sheet for details and recommendations.) However, the melt processing range of unfilled Kynar® homopolymer resins is very broad – from slightly above the melting point of 155°- 170°C (311°-338°F) up to 300°C (572°F). Under certain conditions, Kynar® resin can be processed at higher temperatures. Please consult a technical representative for more information. Kynar® homopolymer is typically processed at temperatures from 180°-265°C (356°-509°F).

In general, Kynar® resins are some of the easiest fluoropolymers to process. Kynar® resins can be recycled up to three times without detriment to their mechanical properties because Kynar® resin is inherently thermally stable and generally does not contain additives. Like most thermoplastics, Kynar® resins discolor and degrade during processing if the processing temperature is too high, the residence time is too long, or the shear rate is too high. Please review the Product Safety section for more information.

Table IV illustrates the linear expansion of various Kynar® and Kynar Flex® resins for the temperature range of -40°C to 85°C.

Figure 4: TGA for Kynar® 740

Table 4: Coefficient of Linear Thermal Expansion (X 10-5/C)

|

RESIN GRADE |

-40°C |

-20°C |

0°C |

23°C |

70°C |

85°C |

|---|---|---|---|---|---|---|

|

Kynar® 710 |

8.9 |

10.8 |

12.2 |

13.4 |

18.3 |

20.4 |

|

Kynar® 740 |

8.6 |

10.2 |

11.4 |

12.4 |

16.7 |

18.8 |

|

Kynar Flex® 2800-00 |

9.7 |

12.9 |

15.7 |

18.5 |

27.4 |

32.6 |

|

Kynar Flex® 2950-05 |

9.7 |

13.6 |

17.1 |

20.2 |

31.3 |

37.0 |

|

Kynar Flex® 3120-50 |

10.2 |

13.1 |

15.5 |

17.5 |

23.0 |

24.7 |

CRYSTALLINITY

The degree of crystallinity of the final Kynar® resin part depends on the resin grade and processing conditions. Rapid cooling (quenching) of the melt impedes crystallization and promotes a smaller crystallite size. Slow cooling or heating below the melting point (annealing) perfects the crystallization process and relaxes stresses. In addition, re-orientation by annealing increases crystallization and long-term performance and stability. With increased crystallinity, parts will have a higher yield strength, modulus and hardness.

ELECTRICAL PROPERTIES

The electrical properties of Kynar® PVDF resins are shown in tabs "Kynar® Homopolymer Series" and "Kynar® Copolymer Series" below. Its combination of high dielectric strength and excellent mechanical properties over a broad temperature range has led Kynar® resin to be used for thin-wall primary insulation and as a jacket for industrial control wiring. With proper shielding, Kynar® PVDF resin can be used as jacketing for high frequency plenum-rated data cables because of its excellent flame and smoke performance.

TENSILE CREEP

Kynar® fluoropolymers are rigid and resistant to creep under mechanical stress and load. Kynar® resins are able to maintain a low tensile creep when subjected to constant stress. For example, when Kynar® 740 resin is subjected to a stress of 0.69 MPa (100 psi), the resin is able to maintain outstanding resistance even at temperatures as high as 140°C (284°F).

OUTGASSING UNDER HIGH VACUUM

Kynar® PVDF resin has inherently low outgassing and low condensable film formation. Kynar® homopolymer resins exhibit extremely low weight loss when exposed to high vacuum. At 100°C (212°F) and a pressure of 5x10-6 torr, the measured rate of weight loss is only 13x10 -11 g/cm2s.

STABILITY TO WEATHER & UV EFFECTS

Many years of outdoor exposure in direct sunlight have little effect on the physical properties of Kynar® PVDF. See photo below for long life exposure to sunlight.

40 Year Florida Test Fence - Exposure of Kynar 500® Architectural Finishes

FUNGUS RESISTANCE

Kynar® PVDF resins do not support growth of fungi when tested as described in Method 508 of Military Standard 810B (June 15, 1967).

OZONE RESISTANCE

Ozone is a powerful oxidizing agent characterized by a high degree of chemical instability. Kynar® PVDF offers excellent chemical resistance to ozone exposure. Please contact an Arkema Fluoropolymers Representative for reports related to this testing.

COMPOUNDED & REINFORCED PRODUCTS

Kynar® PVDF resin is offered in natural, red, black and blue. Kynar® UHM is compounded to offer very high modulus and low mold shrinkage. Kynar® 370 is a filled material in black color to match 2% mold shrink of many polypropylene products. Kynar® 340 and Kynar® 3312C are designed to be used in conductive applications.

KYNAR® PVDF PROCESSING

Below are typical values, not to be construed as sales specifications.

| KYNAR® PVDF GRADE | FABRICATION METHOD |

MELT VISCOSITY ASTM D3835 230°C K POISE @100 SEC-1 |

MELT FLOW RATE ASTM D1238 |

MELT FLOW RATE LOAD lb (kg) |

MELTING POINT |

SPECIAL CHARACTERISTICS |

|---|---|---|---|---|---|---|

| PELLETS | ||||||

| 340 | Injection Molding & Extrusion | 3.0 - 8.0 | 22.0 (10.0) | 165 - 172°C | Conductive | |

| 370 | Injection Molding | 8.0 - 13.0 | 5.0 - 17.0 | 8.36 (3.8) | 165 - 172°C | Low melt shrinkage, carbon filled |

| 460 | Injection Molding & Extrusion | 23.5 - 29.5 | 6.0 - 14.0 | 47.5 (21.6) | 155 - 165°C | Broad molecular weight distribution |

| 705 | Fiber & Multi Filament | 2.0 - 5.0 | 29.0 - 37.0 | 4.75 (2.16) | 165 - 172°C | Very high MFR |

| 710 | Injection Molding | 4.0 - 8.0 | 19.0 - 35.0 | 8.36 (3.8) | 165 - 172°C | |

| 720 | Injection Molding & Extrusion | 6.0 - 12.0 | 5.0 - 26.5 | 8.36 (3.8) | 165 - 172°C | 150°C RTI rating, comes in natural, red or black |

| 740 | Injection Molding & Extrusion | 15.0 - 23.0 | 1.5 - 3.0 | 11.0 (5.0) | 165 - 172°C | |

| 740-02 | Injection Molding & Extrusion | 14.0 - 22.0 | 7.0 - 28.0 | 27.5 (12.5) | 165 - 172°C | With smoke suppressant |

| 740 Black/Red | Injection Molding & Extrusion | 15.0 - 23.0 | 6.0 - 25.0 | 27.5 (12.5) | 165 - 172°C | Pigmented |

| 1000 HD | Injection Molding & Extrusion | 15.0 - 20.0 | 0.5 - 3.0 | 11.0 (5.0) | 165 - 172°C | |

| 6000 HD | Injection Molding | 7.0 - 11.0 | 9.5 - 16.0 | 11.0 (5.0) | 165 - 172°C | |

| 9000 HD | Injection Molding | 5.0 - 8.0 | 16.0 - 40.0 | 11.0 (5.0) | 165 - 172°C | |

| EX-AD 3000 | Extrusion | 12.0 - 18.0 | 2.0 - 7.0 | 11.0 (5.0) | 140 - 145°C | Extrusion aid, lubricated |

| 2500-20 | Extrusion & Molding | 9.0 - 16.0 | 1.0 - 15.0 | 8.36 (3.8) | 117 - 125°C | Highest flexibility |

| 2500-25 | Extrusion & Molding | 9.0 - 16.0 | 1.0 - 15.0 | 8.36 (3.8) | 117 - 125°C | Highest flexibility with smoke suppressant |

| 2750-01 | Extrusion & Molding | 20.0 - 25.0 | 4.0 - 14.0 | 27.5 (12.5) | 130 - 138°C | Very flexible, lubricated |

| 2800-00 | Extrusion | 22.0 - 27.0 | 3.0 - 8.0 | 27.5 (12.5) | 140 - 145°C | Flexible |

| 2800-20 | Extrusion & Molding | 12.0 - 20.0 | 1.0 - 8.0 | 11.0 (5.0) | 140 - 145°C | Flexible |

| 2850-00 | Extrusion & Molding | 23.0 - 27.0 | 3.0 - 8.0 | 27.5 (12.5) | 155 - 160°C | 150°C temperature rating |

| 2850-02 | Extrusion | 16.0 - 20.0 | 10.0 - 20.0 | 27.5 (12.5) | 155 - 160°C | 150°C temperature rating, with smoke suppressant |

| 2850-04 | Extrusion & Molding | 4.0 - 8.0 | 8.0 - 25.0 | 8.36 (3.8) | 155 - 160°C | 150°C temperature rating |

| 2850-07 | Extrusion & Molding | 16.0 - 20.0 | 10.0 - 20.0 | 27.5 (12.5) | 155 - 160°C | 150°C temperature rating |

| 2850 Black | Extrusion & Molding | 16.0 - 28.0 | 4.0 - 18.0 | 27.5 (12.5) | 155 - 160°C | 150°C temperature rating, pigmented |

| 2900-04 | Extrusion & Molding | 5.0 - 12.0 | 4.0 - 17.5 | 8.36 (3.8) | 140 - 145°C | Flexible with smoke suppressant |

| 2950-05 | Extrusion & Molding | 5.0 - 12.0 | 4.0 - 17.5 | 8.36 (3.8) | 130 - 138°C | Very flexible with smoke suppressant |

| 3120-10 | Extrusion & Molding | 5.0 - 12.0 | 4.0 - 17.5 | 8.36 (3.8) | 161 - 168°C | Flexible, 150°C temperature rating |

| 3120-15 | Extrusion & Molding | 5.0 - 12.0 | 4.0 - 17.5 | 8.36 (3.8) | 161 - 168°C | Flexible with smoke suppressant |

| 3120-50 | Extrusion & Molding | 20.0 - 26.0 | 2.5 - 7.5 | 27.5 (12.5) | 161 - 168°C | Flexible, 150°C RTI rating |

| 3030-10 | Extrusion & Molding | 6.0 - 13.0 | N/A | N/A | 161 - 170°C | Flexible, 150°C RTI rating, cold temperature impact |

| 3030-15 | Extrusion & Molding | 6.0 - 13.0 | N/A | N/A | 161 - 170°C | Flexible, 150°C RTI rating, cold temperature impact |

| 3312C | Extrusion & Molding | 17.0 - 23.0 | 7.0 - 15.0 | 22.0 (10.0) | 161 - 168°C | Conductive |

| UHM 6020-20 | Extrusion & Molding | N/A | 4.0-12.0 | 8.36 (3.8) | 165 - 170°C | Reinforced for high strength |

| POWDERS | ||||||

| 201 | Toners | 28.0 - 34.0 | 2.0 - 6.0 | 47.5 (21.6) | 155 - 165°C | |

| 301F | Toners, Dispersion Coatings | 28.0 - 34.0 | 2.0 - 6.0 | 47.5 (21.6) | 155 - 165°C | Fine milled powder |

| 451 | Membranes | 28.0 - 34.0 | 2.5 - 5.5 | 47.5 (21.6) | 155 - 165°C | |

| 461 | Membranes, Binders | 23.5 - 29.5 | 6.0 - 14.0 | 47.5 (21.6) | 155 - 165°C | |

| 711 | Binders, Additives, etc. | 4.0 - 8.0 | 19.0 - 35.0 | 8.36 (3.8) | 165 - 172°C | |

| 721 | Binders, Additives, etc. | 5.0 - 12.0 | 5.0 - 29.0 | 8.36 (3.8) | 165 - 172°C | |

| 741 | Binders, Additives, etc. | 15.0 - 23.0 | 1.5 - 3.0 | 11.0 (5.0) | 165 - 172°C | |

| 761 | Binders, Additives, etc. | 23.0 - 29.0 | 2.0 - 6.0 | 27.5 (12.5) | 165 - 172°C | |

| 761A | Binders, Additives, etc. | 30.5 - 36.5 | 0.5 - 3.5 | 27.5 (12.5) | 165 - 172°C | |

| MG 15 | Binders, Additives, Membranes | 34.0 - 39.0 | 2.0 - 5.0 | 47.5 (21.6) | 162 - 170°C | High molecular weight powder |

| 2751-00 | Binders, Additives, etc. | 20.0 - 25.0 | 4.0 - 14.0 | 27.5 (12.5) | 130 - 138°C | Flexible |

| 2801-00 | Binders, Additives, Membranes | 23.0 - 27.0 | 3.0 - 8.0 | 27.5 (12.5) | 140 - 145°C | Flexible |

| 2821-00 | Binders, Additives, etc. | 12.0 - 20.0 | 1.0 - 6.0 | 11.0 (5.0) | 140 - 145°C | Flexible |

| 2501-20 | Binders, Additives, etc. | 9.0 - 18.0 | 1.0 - 15.0 | 8.36 (3.8) | 117 - 125°C | Very flexible, very soluble |

| LBG | Binders, Additives, etc. | 33.0 - 39.0 | 3.0 - 8.0 | 47.5 (21.6) | 148 - 155°C | Li ion battery applications, membrane |

| HSV 900 | Binders, Additives, etc. | 44.5 - 54.5 | N/A | N/A | 160 - 169°C | Li ion battery applications, membrane |

| HSV 1800 | Binders, Additives, etc. | 40.0 - 46.0 | N/A | N/A | 161 - 167°C | Li ion battery applications |

| OTHER | ||||||

| 2850 PC, WR | Spray Coating Powder, Rotomolding | 4.0 - 8.0 | 8.0 - 25.0 | 8.36 (3.8) | 155 - 160°C | Electrostatic spray, rotolining, rotomolding |

| Latex 32 | Impregnating Fabrics, Membranes | 155 - 160°C | Water base, fine particle size | |||

| 5300/5301 | Polymer Process Aid (PPA) |

<170 | Pellets or powder | |||

* Additional specialty materials are continuously being developed.

| PHYSICAL PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 460 | 1000 SERIES2 | 700 SERIES2 | 370 3 |

| Refractive Index | D542/at Sodium D line 77°F (25°C) | 1.42 | 1.42 | 1.42 | — | |

| Specific Gravity | D792/73°F (23°C) | 1.75 - 1.77 | 1.76 - 1.78 | 1.77 - 1.79 | 1.84 - 1.88 | |

| Water Absorption | D570/68F (20°C) Immersion/24 Hours |

% | 0.02 - 0.04 | 0.01 - 0.03 | 0.01 - 0.03 | 0.04 - 0.06 |

| MECHANICAL PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 460 | 1000 SERIES2 | 700 SERIES2 | 370 3 |

| Flexural Strength @ 5% Strain | D790/73°F (23°C) | psi (MPa) | 7,000 - 9,000 (48 - 62) | 8,500 - 11,000 (58 - 76) | 8,500 - 11,000 (58 - 76) | 20,000 - 30,000 (138 - 207) |

| Flexural Modulus | D790/73°F (23°C) | psi (MPa) | 200,000 - 260,000 (1379 - 1792) |

240,000 - 335,000 (1655 - 2310) |

200,000 - 335,000 (1380 - 2310) |

800,000 - 1,000,000 (5515 - 6895) |

| Tensile Yield Elongation | D638/73°F (23°C) | % | 10 - 15 | 5 - 10 | 5 - 10 | 0 - 4 |

| Tensile Yield Strength | D638/73°F (23°C) | psi (MPa) | 5,000 - 7,500 (34 - 52) | 6,500 - 8,000 (45 - 55) | 6,500 - 8,000 (45 - 55) | 5,000 - 8,000 (34 - 55) |

| Tensile Break Elongation | D638/73°F (23°C) | % | 50 - 250 | 20 - 100 | 20 - 100 | 0 - 20 |

| Tensile Break Strength | D638/73°F (23°C) | psi (MPa) | 4,500 - 7,000 (31 - 48) | 5,000 - 7,000 (34 - 48) | 5,000 - 8,000 (34 - 55) | 5,500 - 8,000 (38 - 55) |

| Tensile Modulus | D638/73°F (23°C) | psi (MPa) | 185,000 - 220,000 (1275 - 1520) |

200,000 - 335,000 (1379 - 2310) |

200,000 - 335,000 (1379 - 2310) |

450,000 - 750,000 (3102 - 5171) |

| Compressive Strength | D695/73°F (23°C) | psi (MPa) | 8,000 - 10,000 (55 - 69) | 10,000 - 15,000 (69 - 103) | 10,000 - 15,000 (69 - 103) | 20,000 - 25,000 (138 - 172) |

| Deflection Temperature | D648/at 264 psi (1.82 MPa) | °F (°C) | 176 - 194 (80 - 90) | 220 - 230 (104 - 110) | 221 - 239 (105 - 115) | 230 - 260 (104 - 127) |

| Deflection Temperature | D648/at 66 psi (0.45 MPa) | °F (°C) | 234 - 284 (112 - 140) | 257- 284 (125 - 140) | 257 - 284 (125 - 140) | 270 - 300 (132 - 149) |

| Impact Strength Notched Izod | D256/73°F (23°C) | Ft-Lb/In | 1.8 - 4 | 1.8 - 4 | 1.8 - 4.0 | 0.75 - 1.50 |

| Impact Strength Unnotched Izod | D256/73°F (23°C) | Ft-Lb/In | 15 - 40 | 20 - 80 | 20 - 80 | 5 - 10 |

| Hardness | D2240/73°F (23°C) | Shore D | 75 - 80 | 77 - 82 | 76 - 80 | 74 - 79 |

| Tabor Abrasion | CS-17 1000g:pad | mg/1000 cycles | 7 - 9 | 5 - 9 | 5 - 9 | — |

| Coefficient of Friction - Static vs. Steel | ASTM D 1894 73°F (23°C) | 0.23 | 0.22 | 0.20 | 0.18 | |

| Coefficient of Friction - Dynamic vs. Steel | ASTM D 1894 73°F (23°C) | 0.17 | 0.15 | 0.14 | 0.12 | |

| THERMAL PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 460 | 1000 SERIES2 | 700 SERIES2 | 370 3 |

| Melting Temperature | D3418 | °F (°C) | 311 - 320 (155 - 160) | 337 - 340 (169 - 171) | 329 - 342 (165 - 172) | 329 - 338 (165 - 170) |

| Tg (DMA) | @ 1 Hz | °F (°C) | -41 - -37 (-40 - -38) | -41 - -37 (-40 - -38) | -41 - -37 (-40 - -38) | -41 - -37 (-40 - -38) |

| Coefficient of Linear Thermal Expansion | D696 | 10E-5/°F | 5.0 - 7.0 | 6.6 - 8.0 | 6.6 - 8.0 | 2.0 - 2.5 |

| Thermal Conductivity | ASTM D433 | BTU-in/hr.ft^2.°F | 1.18 - 1.32 | 1.18 - 1.32 | 1.18 - 1.32 | — |

| Specific Heat | DSC | BTU/Lb.°F | 0.28 - 0.36 | 0.28 - 0.36 | 0.28 - 0.36 | — |

| Thermal Decomposition TGA | 1% wt. loss/in air | °F (°C) | 707 (375) | 707 (375) | 707 (375) | 707 (375) |

| Thermal Decomposition TGA | 1% wt. loss/in nitrogen | °F (°C) | 770 (410) | 770 (410) | 770 (410) | 770 (410) |

| ELECTRICAL PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 460 | 1000 SERIES2 | 700 SERIES2 | 370 3 |

| Dielectric Strength 23°F | D149/73°F (23°C) | KV/Mil | 1.6 | 1.6 | 1.7 | — |

| Dielectric Constant 23°F | D150/100MHz - 100 Hz | 4.5 - 9.5 | 4.5 - 9.5 | 4.5 - 9.5 | 28.8 - 33.5 | |

| Dissipation Factor 23°F | D150/100 Hz | 0.01 - 0.21 | 0.01 - 0.25 | 0.01 - 0.21 | 0.06 - 0.08 | |

| Volume Resistivity | D257/DC 68F (20°C)/65% R.H. | ohm-cm | 2 x 1014 | 2 x 1014 | 2 x 1014 | 1 x 1011 |

| FLAME & SMOKE PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 460 | 1000 SERIES2 | 700 SERIES2 | 370 3 |

| Burning Rate | UL/Bulletin 94 | V - O | V - O | V - O | V - O | |

| Limiting Oxygen Index (LOI) | D2868 | % O2 | 44 | 60 | 44 - 754 | 44 |

1. Typical property values. Should not be construed as sales specifications.

2. The Kynar® 700 PVDF and Kynar® 1000 PVDF series span a wide range of melt viscosities. Please contact an Arkema representative for typical values of specific grades.

3. Filled with graphite powder to reduce mold shrinkage.

4. Kynar® 740 - 02 is offered with flame retardant package that raises LOI

5. (—) not measured

| PHYSICAL PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 2500 | 2750/2950 | 2800/2900 | 2850 | 3120 |

| Refractive Index | D542/at Sodium D line 77°F (25°C) | 1.40 | 1.41 | 1.41 | 1.42 | 1.41 | |

| Specific Gravity | D792/73°F (23°C) | 1.80 - 1.82 | 1.78 - 1.80 | 1.77 - 1.80 | 1.77 - 1.80 | 1.77 - 1.80 | |

| Water Absorption | D570/68F (20°C) Immersion/24 Hours |

% | — | 0.03 - 0.06 | 0.03 - 0.05 | 0.03 - 0.05 | 0.03 - 0.05 |

| MECHANICAL PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 2500 | 2750/2950 | 2800/2900 | 2850 | 3120 |

| Flexural Strength @ 5% Strain | D790/73°F (23°C) | psi (MPa) | 1,500 - 2,500 (10 - 17) | 2,000 - 3,500 (14 - 24) | 3,000 - 5,000 (20 - 34) | 3,000 - 5,000 (20 - 34) | 3,000 - 5,000 (20 - 34) |

| Flexural Modulus | D790/73°F (23°C) | psi (MPa) |

28,000 - 40,000 (192 - 276) |

40,000 - 60,000 (276 - 414) |

70,000 - 110,000 (620 - 827) |

150,000 -180,000 (1034 - 1241) |

90,000 - 120,000 (620 - 827) |

| Tensile Yield Elongation | D638/73°F (23°C) | % | 17 - 25 | 15 - 25 | 10 - 20 | 5 - 15 | 10 - 20 |

| Tensile Yield Strength | D638/73°F (23°C) | psi (MPa) | 1,700 - 2,800 (12 - 19) | 2,000 - 3,100 (14 - 21) | 2,900 - 5,000 (20 - 34) | 4,500 - 6,000 (31 - 41) | 3,500 - 5,000 (24 - 34) |

| Tensile Break Elongation | D638/73°F (23°C) | % | 500 - 800 | 200 - 400 | 100 - 300 | 30 - 200 | 300 - 550 |

| Tensile Break Strength | D638/73°F (23°C) | psi (MPa) | 2,000 - 4,500 (14 - 31) | 2,900 - 4,000 (20 - 27) | 2,500 - 5,000 (17 - 34) | 4,000 - 7,000 (27 - 48) | 5,000 - 7,000 (34 - 48) |

| Tensile Modulus | D638/73°F (23°C) | psi (MPa) |

35,000 - 55,000 (241 - 379) |

40,000 - 65,000 (276 - 448) |

80,000 - 130,000 (551 - 896) |

150,000 - 220,000 (1034 - 1517) |

100,000 - 170,000 (689 - 1172) |

| Compressive Strength | D695/73°F (23°C) | psi (MPa) | 2,000 - 3,000 (14 - 20) | 3,500 - 4,500 (24 - 31) | 4,500 - 6,000 (31 - 41) | 6,000 - 8,500 (41 - 58) | 4,500 - 6,000 (31 - 41) |

| Deflection Temperature | D648/at 264 psi (1.82 MPa) | °F (°C) | 80 - 100 (27 - 38) | 95 - 125 (35 - 51) | 104 - 131 (40 - 55) | 100 - 131 (38 - 55) | 110 - 130 (43 - 54) |

| Deflection Temperature | D648/at 66 psi (0.45 MPa) | °F (°C) | — | 120 - 150 (49 - 65) | 140 - 167 (60 - 75) | 140 - 167 (60 - 75) | 130 - 170 (54 - 77) |

| Impact Strength Notched Izod | D256/73°F (23°C) | Ft-Lb/In | NO BREAK | NO BREAK | 10 - 20 | 2 - 8 | NO BREAK |

| Impact Strength Unnotched Izod | D256/73°F (23°C) | Ft-Lb/In | NO BREAK | NO BREAK | NO BREAK | NO BREAK | NO BREAK |

| Hardness | D2240/73°F (23°C) | Shore D | 50 - 57 | 57 - 62 | 60 - 70 | 70 - 75 | 65 - 70 |

| Tabor Abrasion | CS-17 1000g:pad | mg/1000 cycles | 28 - 33 | 21 - 25 | 16 - 19 | 6 - 9 | 16 - 19 |

| Coefficient of Friction - Static vs. Steel | ASTM D 1894 73°F (23°C) | 0.49 | 0.55 | 0.33 | 0.26 | 0.31 | |

| Coefficient of Friction - Dynamic vs. Steel | ASTM D 1894 73°F (23°C) | 0.54 | 0.54 | 0.33 | 0.19 | 0.30 | |

| THERMAL PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 2500 | 2750/2950 | 2800/2900 | 2850 | 3120 |

| Melting Temperature | D3418 | °F (°C) | 242 - 257 (117 - 125) | 266 - 280 (130 - 138) | 284 - 293 (140 - 145) | 311 - 320 (155 - 160) | 322 - 334 (161 - 168) |

| Tg (DMA) | @ 1 Hz | °F (°C) | -46 - -40 (-43 - -40) | -44 - -40 (-42 - -40) | -42 - -39 (-41 - -39) | -41 - -37 (-40 - -38) | -42 - -39 (-41 - -39) |

| Coefficient of Linear Thermal Expansion | D696 | 10E-5/°F | 8.5 - 10.8 | 9.0 - 12.0 | 7.0 - 10.3 | 7.0 - 10.3 | 7.0 - 10.3 |

| Thermal Conductivity | ASTM D433 | BTU-in/ hr.ft^2.°F | 1.00 - 1.25 | 1.00 - 1.25 | 1.00 - 1.25 | 1.00 - 1.25 | 1.00 - 1.25 |

| Specific Heat | DSC | BTU/Lb.°F | 0.28 - 0.36 | 0.28 - 0.36 | 0.28 - 0.36 | 0.28 - 0.36 | 0.28 - 0.36 |

| Thermal Decomposition TGA | 1% wt. loss/in air | °F (°C) | 707 (375) | 707 (375) | 707 (375) | 707 (375) | 707 (375) |

| Thermal Decomposition TGA | 1% wt. loss/in nitrogen | °F (°C) | 770 (410) | 770 (410) | 770 (410) | 770 (410) | 770 (410) |

| ELECTRICAL PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 2500 | 2750/2950 | 2800/2900 | 2850 | 3120 |

| Dielectric Strength 73°F | D149/73°F (23°C) | KV/Mil | 0.8 - 1.1 | 1.1 - 1.3 | 1.3 - 1.5 | 1.3 - 1.6 | 1.3 - 1.5 |

| Dielectric Constant 73°F | D150/100MHz - 100 Hz | 4.5 - 13.5 | 3.8 - 12.1 | 3.5 - 10.6 | 3.5 - 10.2 | 3.2 - 10.2 | |

| Dissipation Factor 73°F | D150/100 Hz | 0.05 - 0.29 | 0.02 - 0.24 | 0.02 - 0.21 | 0.01 - 0.22 | 0.02 - 0.19 | |

| Volume Resistivity | D257/DC 68F (20°C)/65% R.H. | ohm-cm | 2 x 1014 | 2 x 1014 | 2 x 1014 | 2 x 1014 | 2 x 1014 |

| FLAME & SMOKE PROPERTIES1 | STANDARD/CONDITIONS | UNITS | 2500 | 2750/2950 | 2800/2900 | 2850 | 3120 |

| Burning Rate | UL/Bulletin 94 | V - O | V - O | V - O | V - O | V - O | |

| Limiting Oxygen Index (LOI) | D2868 | % O2 | 42/952 | 43/952 | 42/752 | 43/752 | 42/952 |

1. Typical property values. Should not be construed as sales specifications.

2. Optional products available with higher LOI.

3. ( - ) not measured.