Rilsan® HT - high temperature polyamides

Rilsan® HT - The first flexible polyphthalamide (PPA)-based material range to replace metal in tubing for high temperature automotive and other demanding industrial applications. This entirely new class of flexible, partially bio-based polyphtalamide combines the high temperature resistance of conventional PPA grades with a flexibility unprecedented in this material class, creating opportunities to replace metal that were previously unimaginable.

How is the Rilsan® HT range different from classic PPA?

Since classic PPA resins are known for their inherent brittleness limiting their use to rigid or injection-molded parts, Arkema has developed the Rilsan® HT series specifically to fill this gap. Due to its specific polymer matrix, which is based largely on long-chain chemistry, the Rilsan® HT range stands out above all by a flexibility previously unknown in this material group. This revolutionary flexibility of Rilsan® HT grades offer a step-change in PPA-based materials and makes it the first range of flexible PPA extending metal substitution to new applications like severe engine-compartment service or other demanding industrial uses.

In contrast to other high-temperature thermoplastics, Rilsan® HT resins also exhibit excellent long-term resistance to thermo-oxidation and chemical aging at high temperatures, as well as very low moisture absorption that produces exceptional dimensional stability and low tendency to creep.

Key properties

The Rilsan® HT series offers both the properties of long-chain Rilsan® PA11 and classic PPA, combining the high temperature resistance of conventional PPA grades with a flexibility previously unknown in this material class.

Low moisture uptake, excellent long-term resistance to thermo-oxidative and chemical aging, as well as ease of processing complete the unique performance spectrum of Rilsan® HT resins.

Focus: Flexibility

Rilsan® HT grades are the first PPA's to combine the high temperature resistance of conventional PPA grades with unprecedented flexibility for this class of materials. Largely based on long-chain chemistry, Rilsan® HT grades offer the optimum synergy of long-chain Rilsan® PA11 and classic PPA, resulting in outstanding flexibility and ease of processing.

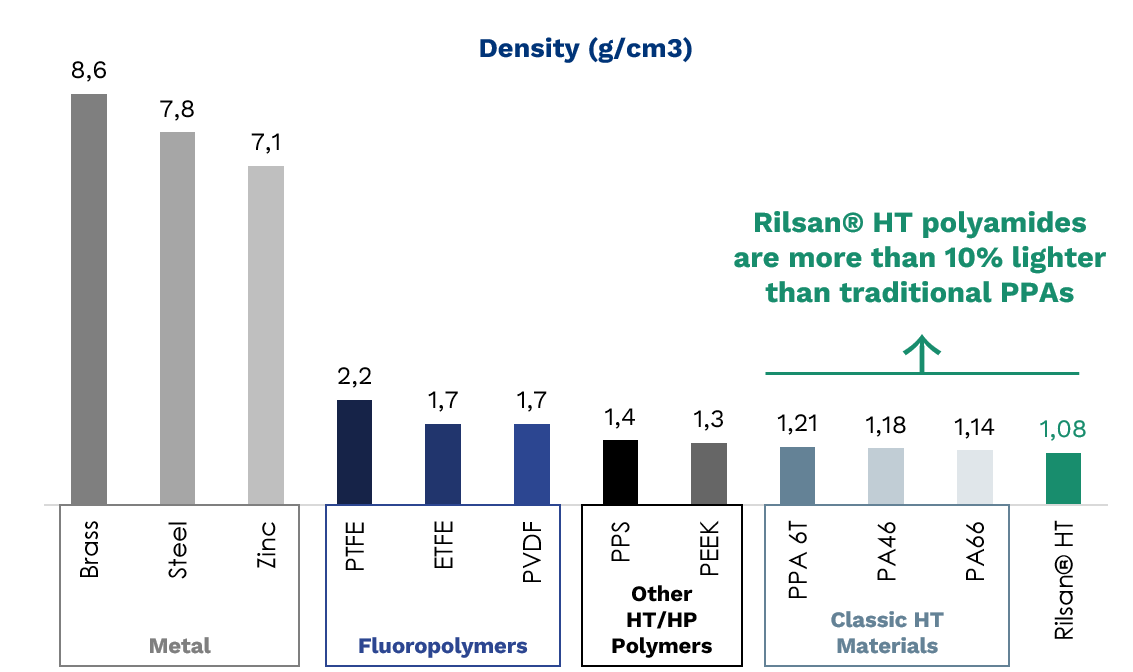

Focus: Low density, lightweighting

Main applications

Other markets:

- Air management (e.g. brake booster)

- Oil management (e.g. cooling line)

- Aqueous media management (e.g. SCR)

- Aggressive media management (e.g. blow-by)

- ...

Other markets:

- Pneumatic / hydraulic

- Cable protection

- Monofilament

- Fibers

- ...

Processing

Rilsan® HT grades process similarly to other high performance, long-chain aliphatic polyamides:

- Extrusion: use the same equipment as used for PA11/PA12

- Injection: use the same equipment as used for PA11/PA12

- Extrusion blow molding: use the same equipment as used for PA/PE

In addition, Rilsan® HT resins are also amenable to further processes such as spunbonding (a nonwoven manufacturing technique), coating, and filament production. Thanks to its very low moisture absorption, Rilsan® HT grades offer a large processing window compared to classic PPA-based resins and is easy to handle overall also compared to PPS. This avoids additional upstream or downstream production steps, and helps reduce scrap levels.