Formulate High Performance Coatings with the Orgasol® and Rilsan® D Range of Coating Additives

Multifunctional Coating Additives

The Orgasol® and Rilsan® D products are high-performance, multi-functional coating additives based on polyamide chemistry. These materials are problem solvers for your waterborne, solvent-borne and UV-coating formulations. The products provide benefits both in terms of coating performance and processability of the coating.

Orgasol® polyamide powders

Orgasol® is a range of high-performance ultra fine

polyamide powders used as additives in coatings, ink varnishes, and technical compounds.

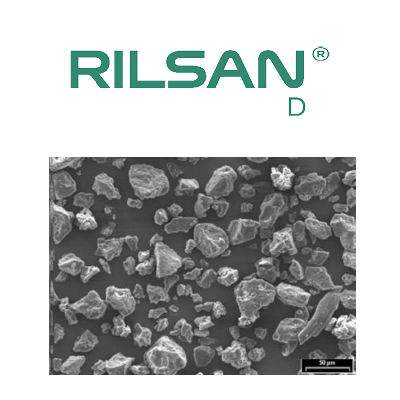

Rilsan® D fine powders

Rilsan® D fine powders are a range of high-performance polyamide powders manufactured from a 100% renewable resource (castor plant) and are used as an additive in coatings.

Key advantages of Orgasol® & Rilsan® D polyamide powders

Comparison between Orgasol® Powders and Other Coating Additives

The Orgasol® and Rilsan® D products provide a multitude of benefits to coating formulations. However, the best fit for the use of these materials is when the coating formulator wants to improve two or more aspects of coating performance. For example, if a formulator is happy with a formulation and just needs to lower the gloss, the formulator should use silica. However, if the formulator wants to reduce gloss and improve abrasion resistance or reduce gloss without a viscosity spike making the formulation unprocessable, these are ideal situations for the Orgasol® and Rilsan® D technology. In these types of situations, the use of the Orgasol® or Rilsan® D products will help create a formulation that is both technically and commercially viable.

Orgasol® and Rilsan® D Fine Powders Particle Size Distribution

The Arkema patented polymerization process used to produce Orgasol® ultrafine powder leads to a product with a unique shape and narrow particle size distribution. Made without the grinding step used to manufacture most of other powders, Orgasol® offers spherical particles, in seven sizes from 5 to 60 microns, and a very accurate control of particle size distribution.

Download the Orgasol® and Rilsan® D Coating Additives Brochure

In this brochure, we present the full product range of multifunctional additives. You can discover a detailed explanation of the benefits of the additives in various coatings including water-based varnishes, UV finishes, UV-curable overprint varnishes, coil coating, water-borne PU and acrylic wood finishes.

Download the brochure here