Orgalloy®

High Performance Polyamide Alloys

Best of Both Worlds

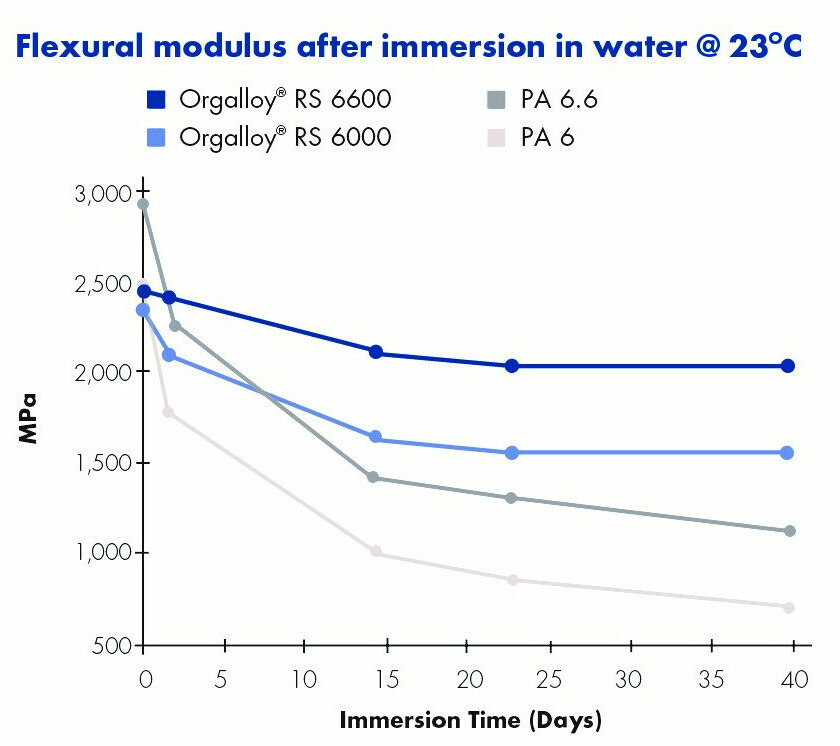

Orgalloy® polyamide alloys combine the important physical and chemical properties of short-chain polyamides with the economic and process advantages of polyolefins. They are designed to offer improved dimensional stability, lower density and better mechanical properties than PA 6 and PA 6.6 resins.

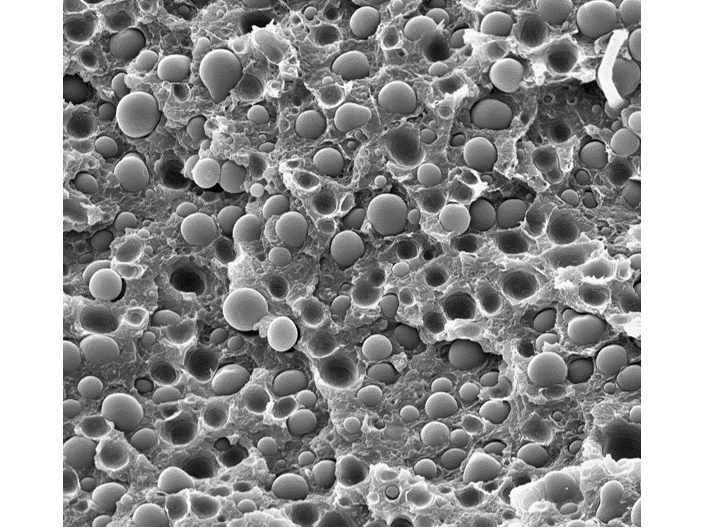

Immiscible blend of Polyamide and Polyolefin.

Polyamide 6 or 6.6 based alloy with a dispersed polyolefin phase.

Combination of Benefits

Polyamide 6 or 6.6

- Mechanical strength

- Thermal resistance

- Barrier performance to HCs

- Chemical resistance to HCs

Polyolefin

- Easy processing

- Moisture inertness

- Inertness to polar solvents

- Impact resistance

The combination results in:

ORGALLOY®

- Low density

- Dimensional stability

- Constant mechanical properties after moisture recovery

- Chemical resistance

- Barrier properties

- Thermal resistance

- Compatibility with other polymers

- Easy processing & high productivity

Superior Barrier Properites Compared to PA 6, 6.6

- Solvent

- Alcohol

- Glycol

- Acids

- Anti-crush insulation (foam)

- Moisture

- Bases

- Hydrocarbon

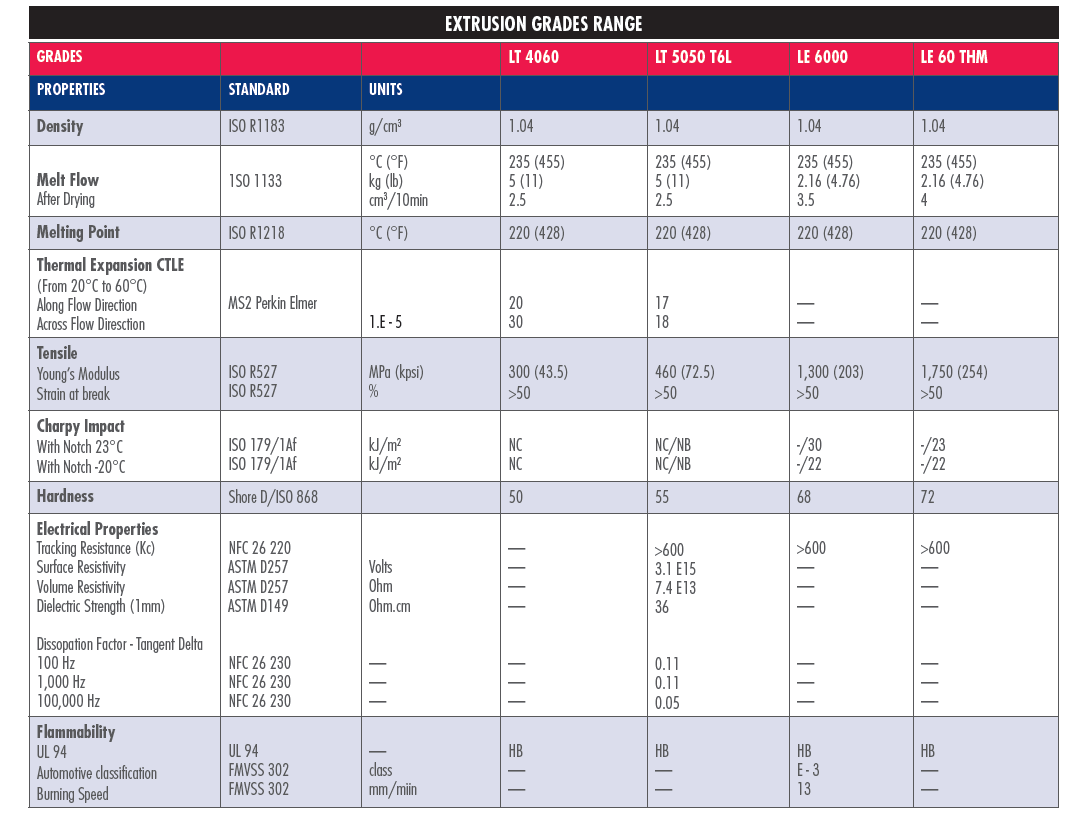

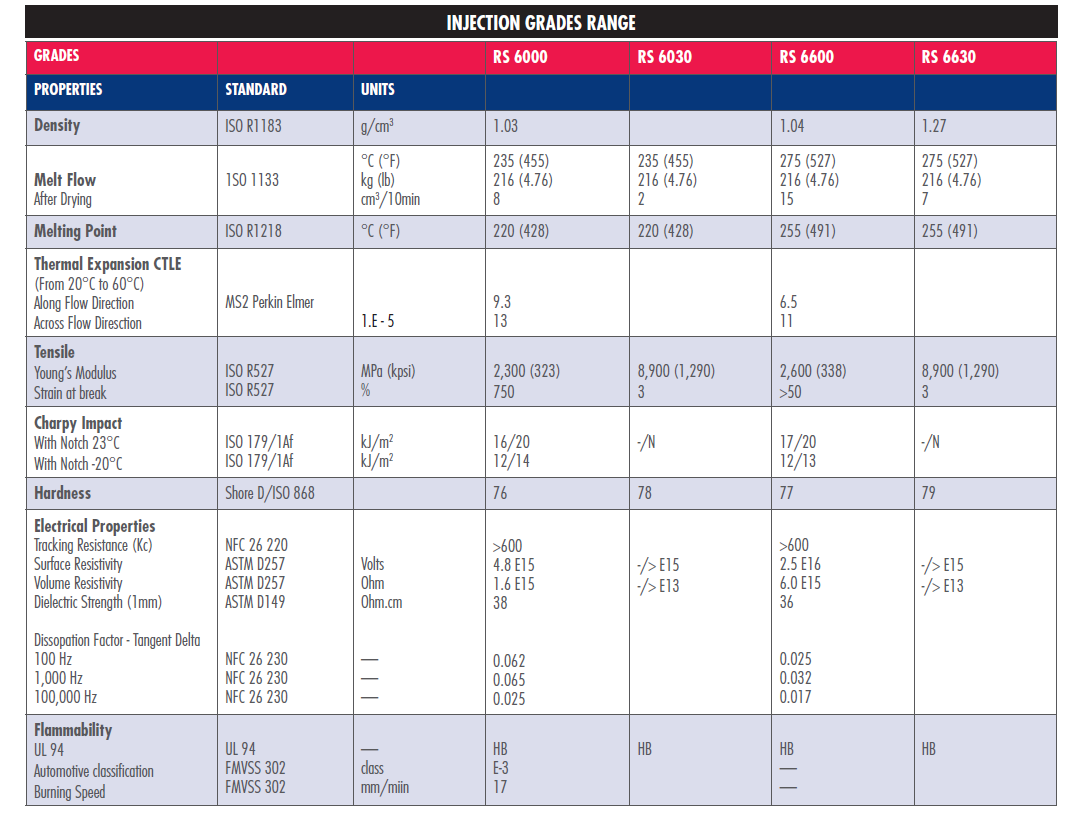

Available in extrusion and injection molding grades

Download the Orgalloy® Polyamide Alloys Brochure

Contents: Nomenclature, Properties & data, Tubes, mandrels, profiles, cables, Blow molding, Film and packaging, Injection molding, Processing information, Applications