Key Properties

of Pebax® Elastomers

Due to the versatility of Pebax® elastomers, every year there are new applications utilizing this polymer in motion. Across the entire range of soft/flexible to hard/rigid grades, Pebax® polymers exhibit a wide range of beneficial properties.

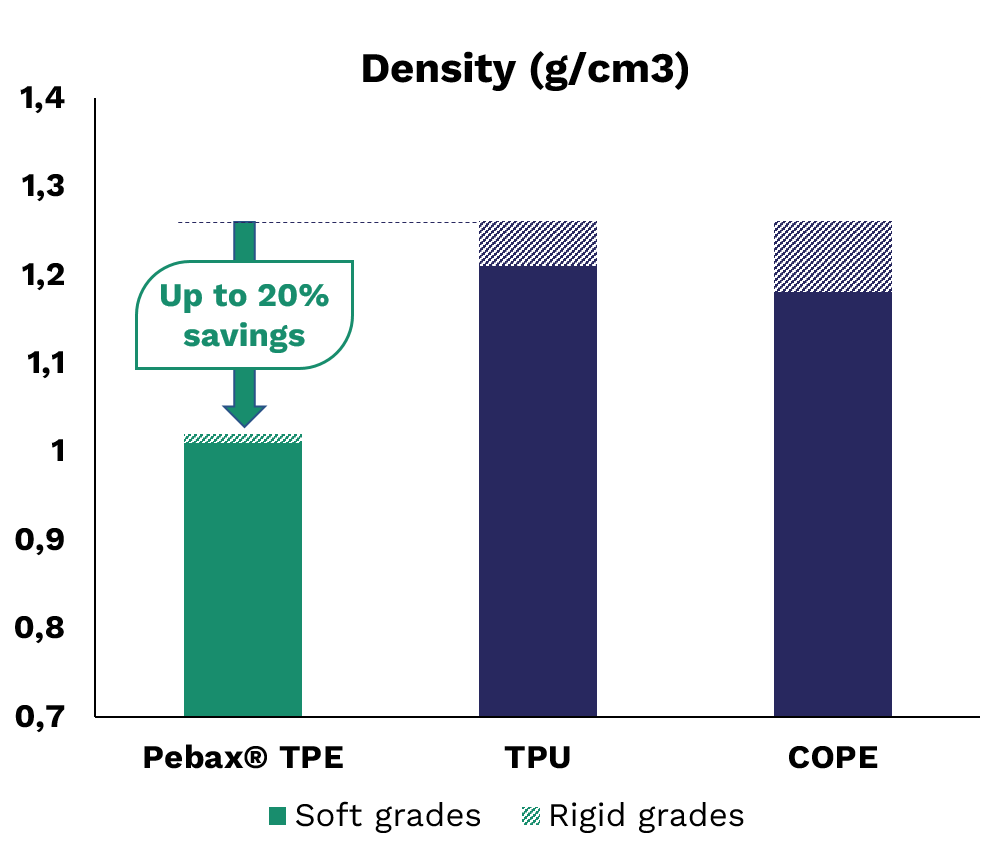

Lightweight

Pebax® resins are extremely light - usually more than 20% lighter than competitive polymers.

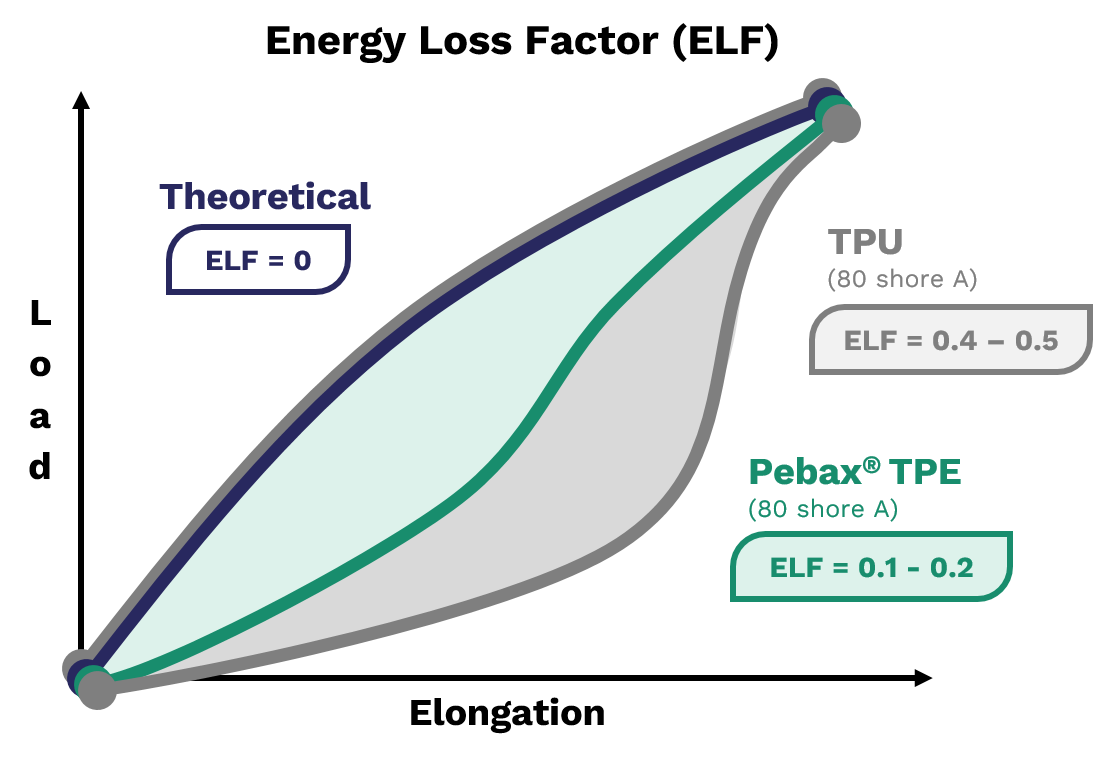

Energy Return

Pebax® polymers also offer extremely efficient energy return during repeated flexural cycling. This very low hysteresis level means that a high percentage of the energy put into flexing the polymer (i.e. the step of an athlete) is returned during rebound. Comparatively, Pebax® elastomers also offer a much lower energy loss factor (ELF) than materials like TPU.

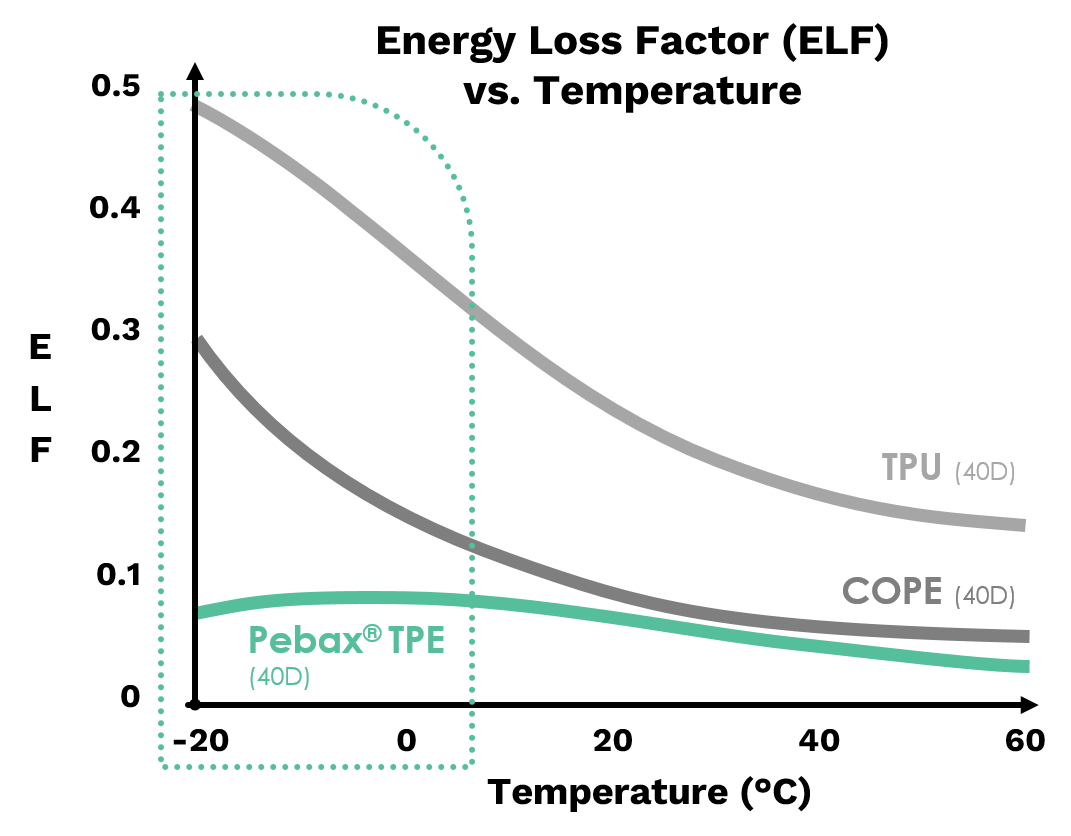

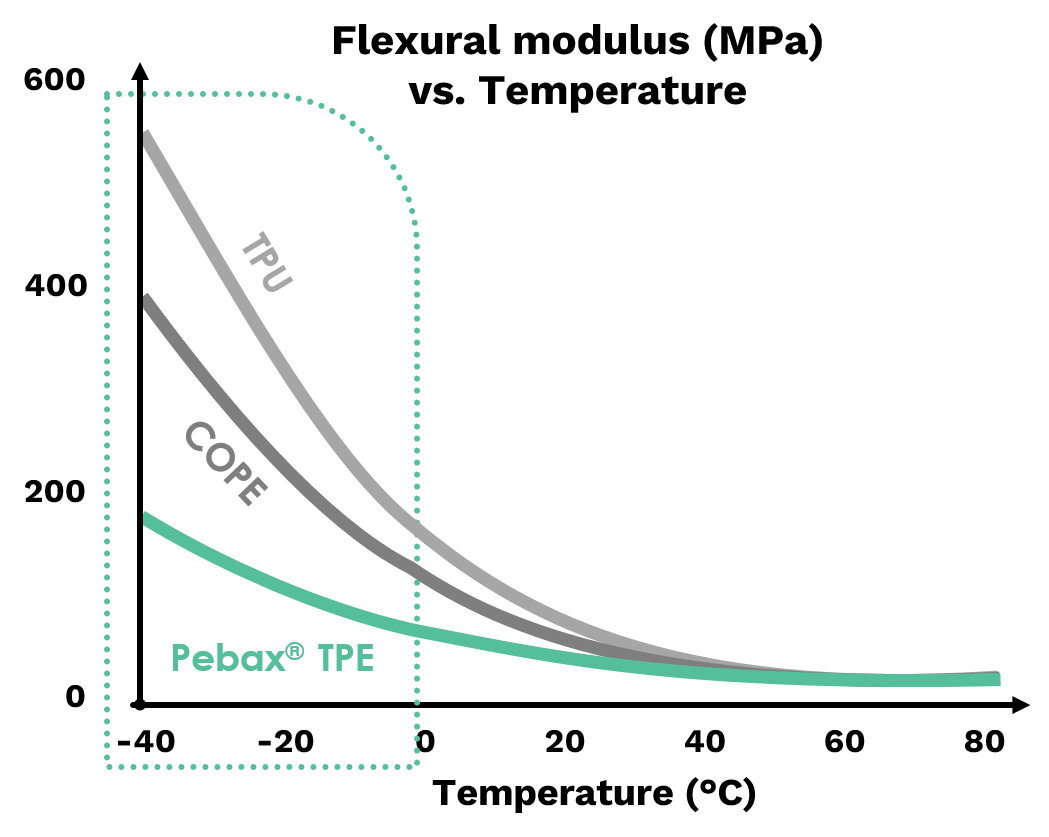

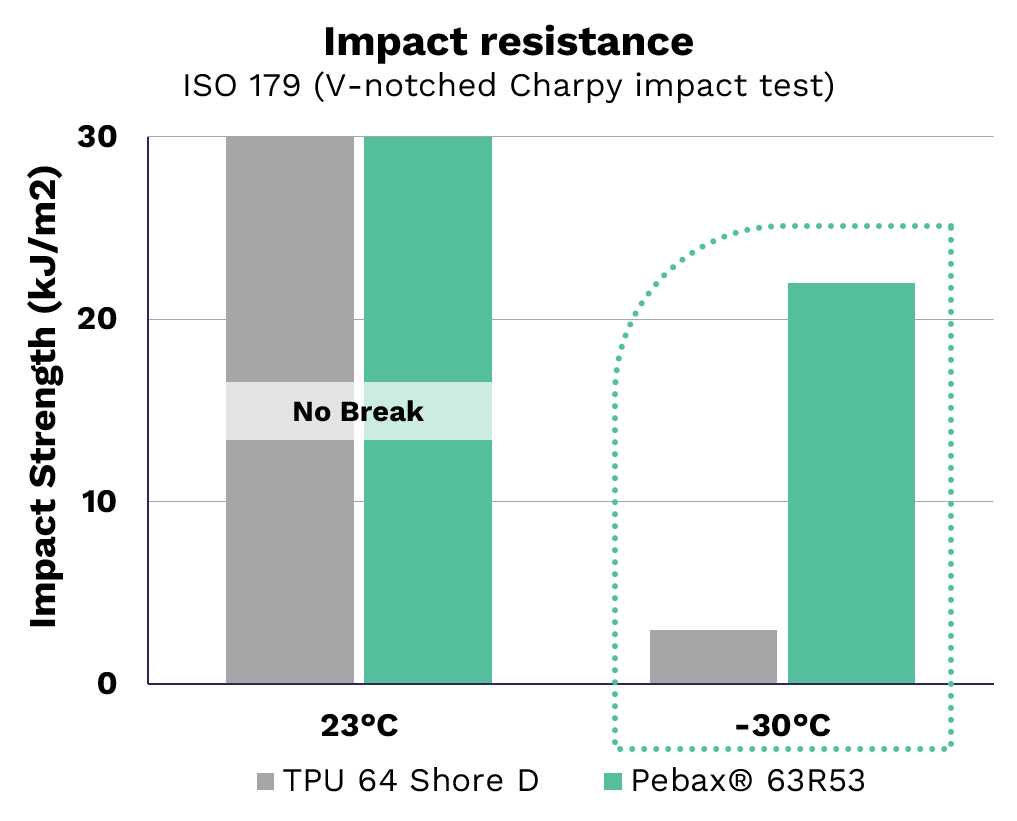

High Performance at Low Temperature

Thanks to the low glass transition temperature of its polyether phase, the energy loss factor of Pebax® resin remains low, even in sub-zero environments. This allows Pebax® elastomers to maintain flexibility and display almost no increase of its elastic modulus compared to other materials at cold temperatures that experience cold stiffening and even become brittle, making them susceptible to cracking. Pebax® polymers also have incredibly strong cold impact resistance.

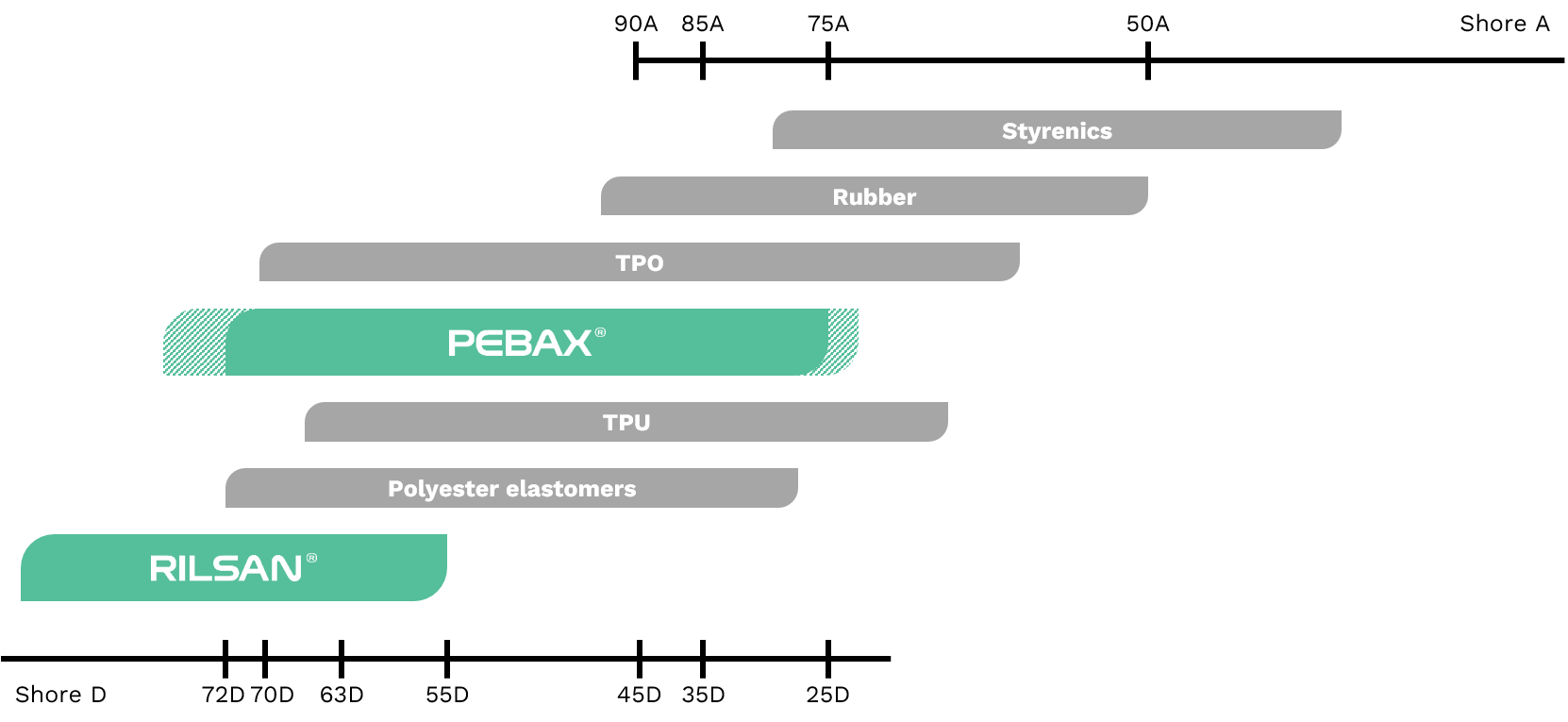

Range of Hardness & Flexibility

The Pebax® family spans a wide range of hardness and flexibility values, which provides freedom when designing parts. It's also possible to overmold hard and soft Pebax® grades with each other and even other materials like PA11, PA12, and TPU to attain effective combinations of properties.

Antistatic

Pebax® resin can be used as an additive in polymer matrices to create immediate permanent antistatic properties. The resin forms a 3D network in the polymer matrix and does NOT migrate to the surface, even when subjected to high and low humidity conditions where chemical agents can be very inefficient.

Breathable

Pebax® polymers can be processed into monolithic, non-porous, non-woven films for use in applications that require breathability. Hydrophilic grades enable the transfer of water vapor molecules (breathability) while protecting from moisture penetrating the surface (water-resistance).

Pebax® thermoplastic elastomers' chemical resistance

In general, Pebax® thermoplastic elastomers possess good resistance to chemicals. They may swell in certain solvents (this tendency is stronger for softer grades). Any application that exposes Pebax® thermoplastic elastomers to chemicals must be considered a special case. It is particularly important to contact Arkema’s technical team, and when possible, carry out tests under real-life conditions. Download the document with details indicating the resistance of Pebax® material grades to common solvents and chemicals.

Pebax® thermoplastic elastomers' chemical resistance sheet