Feb 15, 2024 - 5 min

PVDF by Emulsion: the go-to Enabler for Solvent-free Technology in Battery Cell Manufacturing

In recent years, the demand for high-performance batteries has surged, driven by the exponential growth of electric vehicles, and renewable energy storage solutions. At the heart of this revolution lies battery cell manufacturing, a crucial process that determines the efficiency and reliability of modern energy storage systems.

Battery electrode and separator coating

In this white paper, we delve into the dynamic world of a battery electrode and separator coating manufacturing, examining the case of a new battery cell manufacturing process versus PVDF emulsion technology. Polyvinylidene Fluoride (PVDF), a well-established binder in the Lithium or Sodium-ion battery cell manufacturing industry, satisfies simultaneously the most pivotal material characteristics as a cathode binder or separator coating.

The following are the important characteristics required for lithium-ion battery technology today:

- High Electrochemical Resistance & High Purity

- Mechanical stability

- Processability

Case 1: Water-based Technologies - Separator Coating

In the first case, we explain how applying the conventional solvent-based technology to the water-based system does not give the desirable results in terms of adhesion and particle size. We demonstrate how the emulsion process results in precise and optimized PVDF coatings for battery cell separator coating.

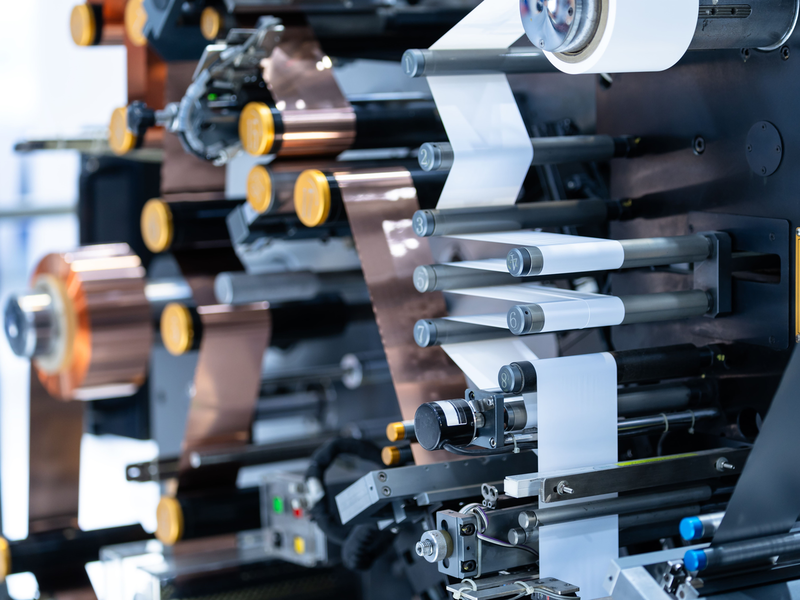

Case 2: Dry Process - Electrode Manufacturing

In the second case, we decode the dry process electrode manufacturing and how our PVDF can achieve the optimum in the deagglomeration process of the secondary particles.

See also

Back to all articles- Case Study

- Expertise articles

- Expertise articles