Battery Materials for Cell Manufacturing

Parts of a Lithium Ion Battery

- Electrodes (anode & cathode)

- Active material (LFP, LCO, NMC, Graphite, others)

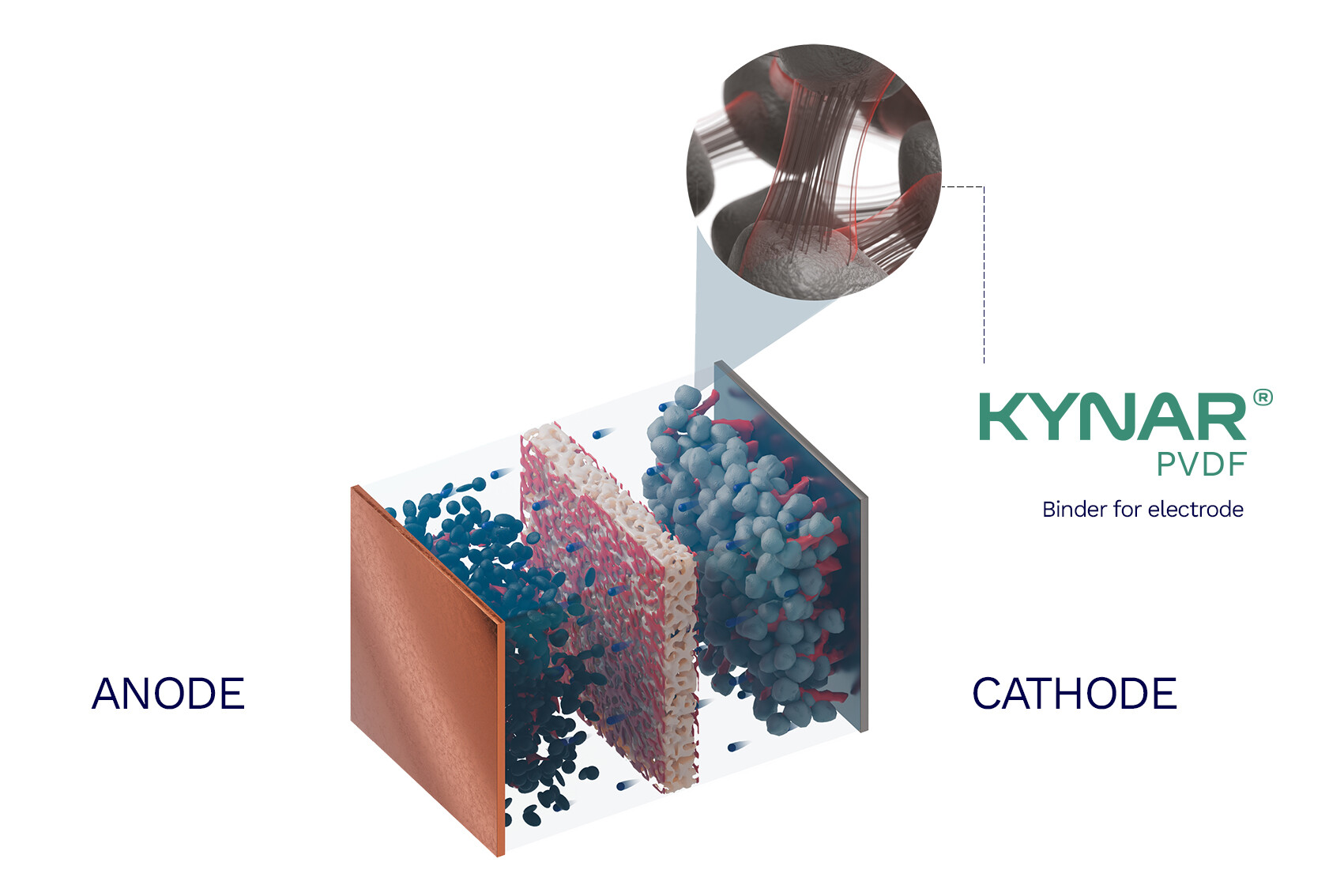

- Electrode binder (Kynar® PVDF - HSV series)

- Separator (polyolefins, others)

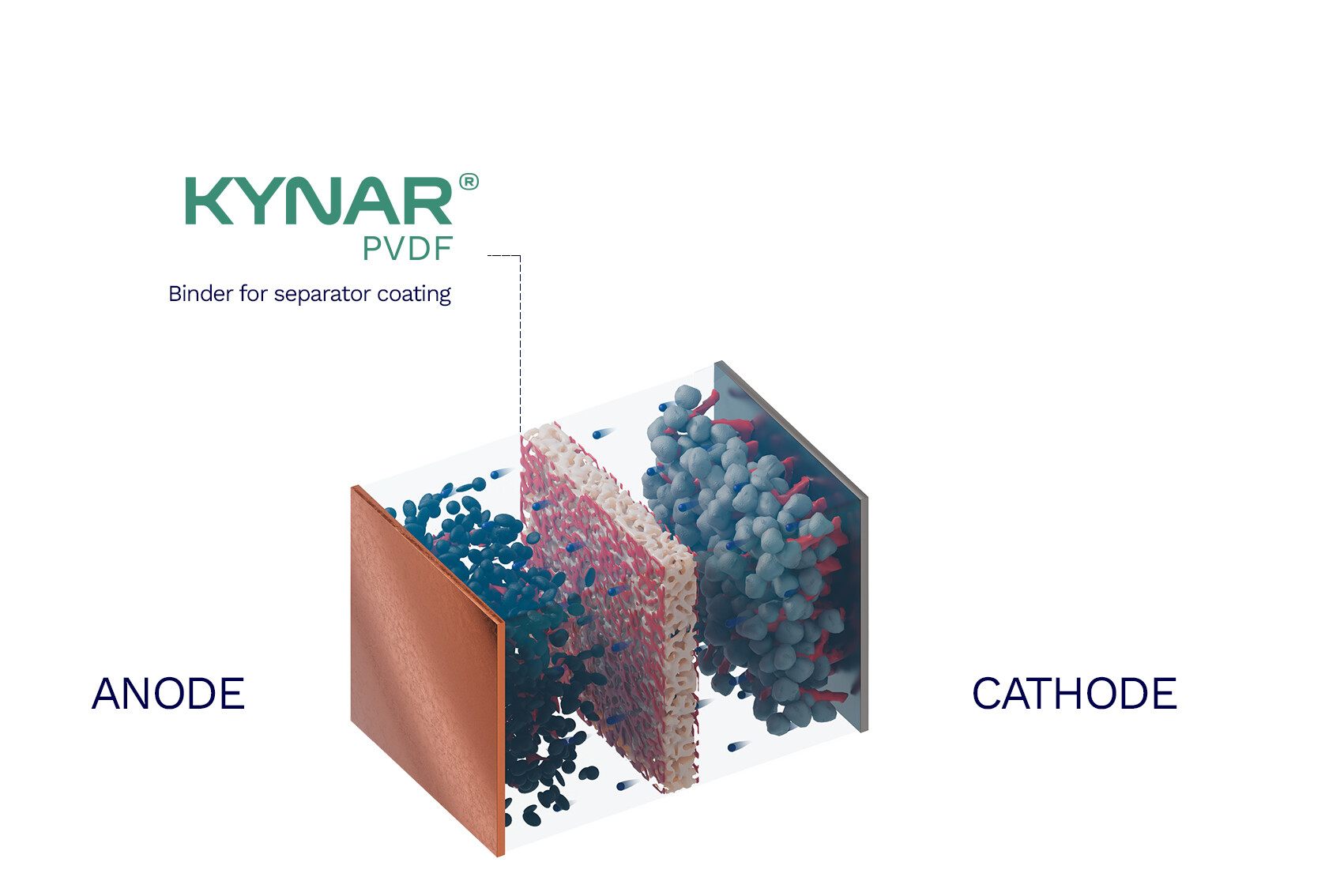

- Separator coating (Kynar Flex® PVDF - LBG series)

-

Foranext® LiFSI and LiTDI for lithium-ion batteries

Electrode binders: Kynar® HSV series

- Easy processing

- High adhesion/lower loading

- Lower swelling in electrolyte

- Lower electrode resistivity

- High voltage stability

Separator coatings: Kynar Flex® LBG series

- High electrode adhesion (wet & dry)

- High voltage stability

- High dimensional stability

- Controlled crystallinity

- Nanoceramic compatibility for solvent & waterborne technologies

Tailor-Made Performance PVDF

Arkema has been a pioneer in the development of high performance PVDF resins and flexible copolymers for several decades. Our proprietary process allows careful tailoring of molecular weight, particle size, crystallinity, and functionality.

Emulsion PVDF was originally designed, more than 50 years ago for high-end construction coatings where a small particle size is required to get a high level of gloss and smooth surface finish.

Higher Surface Area = Easier Dissolution = Faster Processing.

Today, in battery applications, those small particles, combined with their unique aggregated structure, result in a fast dissolution rate into NMP or Acetone as opposed to large suspension particles where NMP diffusion into the beads may be extremely slow. The small particles are also key in enabling a revolutionary ‘dry process mixing’.

Cathode Binder Innovation

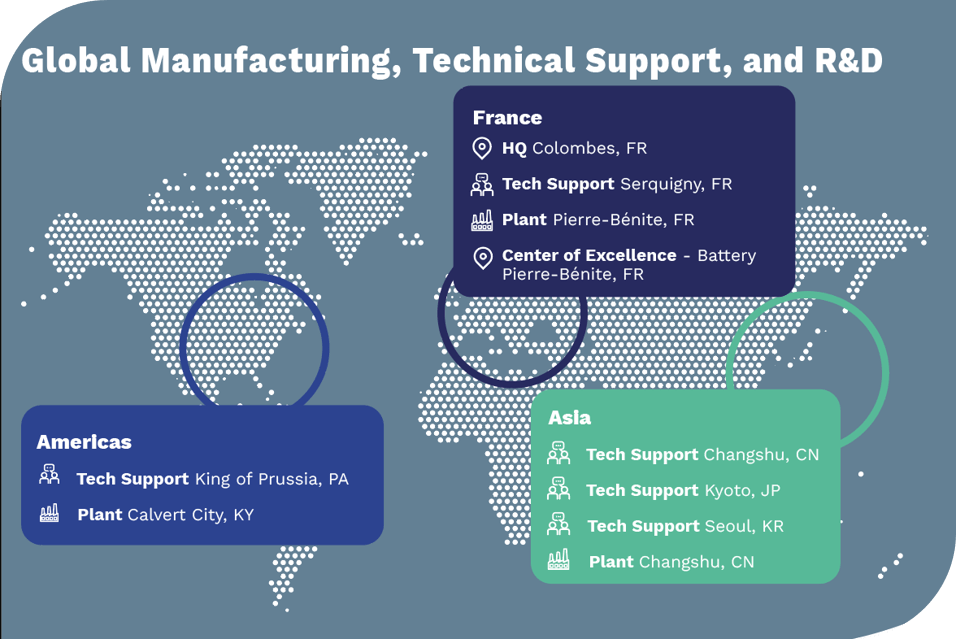

Binder innovation is at the core of our strategy in the battery cell manufacturing industry. Arkema is committed to an exciting future in binder development that will drive safer, higher-performing cells. Arkema’s King of Prussia battery innovation hub in the USA leads the way and we invite customers to collaborate with us as we push the boundaries of cutting-edge technologies (e.g. high nickel binders, waterborne solutions, dry process prototypes). Our team is also eager to assist from our satellite technical centres in China, France, Japan, and Korea.

PVDF by Emulsion: the go-to Enabler for Solvent-free Technology in Battery Cell Manufacturing

Download the white paper

In this white paper, we delve into the dynamic world of a battery electrode and separator coating manufacturing, examining the case of a new battery cell manufacturing process versus PVDF emulsion technology. Polyvinylidene Fluoride (PVDF), a well-established binder in the Lithium or Sodium-ion battery cell manufacturing industry, satisfies simultaneously the most pivotal material characteristics as a cathode binder or separator coating.

Arkema's R&D Hub For Battery Cell Expertise

Expanded in 2021, Arkema’s Battery Center, in Lyon, plays a key role in this transition and strives to develop high-performing materials for current lithium cell technologies as well as next-generation batteries, such as semi-solid, solid and sodium. Closely connected with other research centers, in Asia and the USA, the center is equipped with cutting-edge technologies allowing battery manufacturers to leverage reliable and real-life data to speed up the development of the next generation of batteries.

Discover more about Arkema's Battery Center

Arkema's full portfolio of advanced materials for battery

At Arkema, we have a wide portfolio of advanced materials covering applications inside and outside the cell, from cell to module and battery pack assembly up to battery system integration into the vehicle. Our solutions help to optimize performance and improve the battery energy density, duration, weight reduction and recharging time.

Global Supply and Support