Kepstan® PEKK Resins

for Wire Coatings

"OUTSTANDING ELECTRICAL INSULATING PROPERTIES FOR EXTREME CONDITIONS"

Kepstan® PEKK for High Performance Wire Coating

Kepstan® PEKK offers a high temperature, chemically inert, and abrasion resistant wire coating for conductors operating in harsh environments, including aerospace and oil and gas applications. Kepstan® PEKK also maintains insulative properties at elevated temperatures.

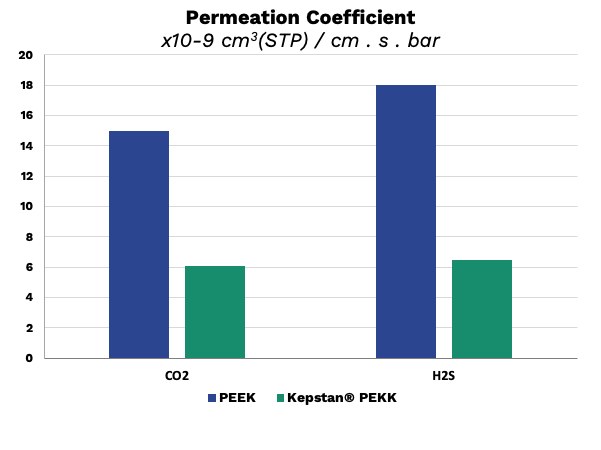

Kepstan® PEKK shows great barrier performance, critical for oil and gas applications.

Excellent Flame, Smoke, and Toxicity Properties

| Gas | Flaming | Non-Flaming |

|---|---|---|

| Carbon Monoxide | 280 ppm |

None Detected |

| Carbon Dioxide | 2449 ppm |

None Detected |

| Nitrogen Dioxide | None Detected |

None Detected |

| Sulfur Dioxide | None Detected |

None Detected |

| Hydrogen Chloride | None Detected |

None Detected |

| Hydrogen Fluoride | None Detected |

None Detected |

| Hydrogen Bromide | None Detected |

None Detected |

| Condition | Specification | Unit | Value | |

|---|---|---|---|---|

| Flammability Rating (aero) | 0.8 mm | UL 94 | - | V-0 |

| Fire Protection on Railway Vehicles (train) | 2 mm |

NF EN 45545 R22 / R23 |

- | HL3 |

| Heat Release Rate (OSU) | 3.0 mm | FAR 25.853 | KW/m2 | 43.52 |

| Limiting Oxygen Index | 1.6 mm | ISO 4589-2 | %O2 | 35-35 |

Expanding Capabilities With Alloys

Kepstan® PEKK offers a unique ability to be alloyed with other polymer materials. Arkema offers several alloyed options to improve specific properties such as glass transition temperature, dielectric performance, or even cost reduction. Contact us to discuss your unique wire insulation needs!