New Developments

in Wire & Cable

UL 444 Mandrel Wrap Test

Mandrel Wrap testing was performed on a series of jacketed communications cables per UL444. Communication cables were jacketed with 0.020 inches of various Kynar Flex® grades (final diameter of 0.210 inches). Mandrel sizes used were 2.4 inches (12x cable diameter) and 1.3 inches (6.5x cable diameter) at temperatures ranging from -20°C to -60°C. The results of this work are summerized in the following table.

|

Sample Name |

Temperature (°C) |

||||

|---|---|---|---|---|---|

| -20 | -30 | -40 | -50 | -60 | |

|

Kynar Flex® 3120-10 |

PASS | PASS | PASS | PASS | PASS |

|

Kynar Flex® 3120-15 |

PASS | PASS | PASS | PASS | PASS |

|

Kynar Flex® 2500-25 |

PASS | PASS | PASS | PASS | PASS |

|

Kynar Flex® 3120-50 |

PASS | PASS | PASS | PASS | PASS |

|

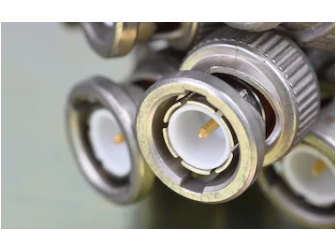

Using Kynar® PVDF in Connector Design

|

Advantages of Kynar® PVDF over other Materials

|

|---|

Useful information

NEW Kynar® PVDF Foam Technology being developed with a focus on wire and cable applications

- Added as a concentrate

- Ease of Processing (wide window)

- Specifically designed to foam a full range of Kynar® PVDF products (rheology and flexibility)

- Density reduction of 10% to +70%

- Improved crush resistance and stripping

New Foam technology providing improved flame and smoke performance

- Higher “Improved” Plenum Performance

- UL 2024 rating of 0/0 obtained for PVDF foamed microducts at weight reductions ranging from 50% to 70%.