Biopharmaceutical Industry

The biopharmaceutical industry requires materials that have excellent properties for the processing of specialty chemicals, high purity water, and resistance to various methods of sterilization required in the processing of pharmaceuticals. Select Kynar® grades meet the extreme demands and regulatory requirements of this growing industry.

View and Download Our Kynar® PVDF Brochures!

Kynar® PVDF: Performance and Characteristics Brochure

Kynar® PVDF: Chemical Resistance Chart

KYNAR® PVDF: COMPONENTS BROCHURE

Product Overview: Kynar® PVDF

For Biopharmaceutical applications requiring excellent resistance to acids, chlorine and bromine, Kynar® PVDF is a commonly used material of construction for process piping, pumps, tubing, tanks, filters and other fluid handling components. In addition to the chemical resistance to the process stream, Kynar® PVDF is also resistant to many common forms of sterilization such as ozonation, chemical bleaching, and steam-cleaning.

Common Kynar® PVDF Applications

|

Application |

Instead of: |

Max Temp: |

Advantages: |

|

Exposure to chlorinated & brominated chemicals |

Titanium PTFE-lined steel PFA-lined steel |

275°F (135°C) |

Lower cost

Easier installation

Lower permeation |

|

Exposure to hot acids (e.g.: HF, HCl, H2SO4, HNO3, chromic, HBr) |

Titanium Alloy 20 PTFE-lined steel |

275°F (135°C) |

Lower cost Easier installation Chemical resistance at varied concentrations |

|

Alcohol & acids /chlorides /hydrocarbons |

Polypropylene HDPE |

194°F (90°C) |

Broad chemical resistance at varied concentrations |

|

High pressure & high temperature |

PVC Polypropylene CPVC |

285°F (141°C) and 340 psi at RT |

High temperature rigidity High pressure rating Broad chemical resistance |

Easy Processing for a Complete Solution

The thermoplastic Kynar® PVDF family of resins is characterized by ease of welding and post forming. As Kynar® PVDF has a wide window of processing between the melting point and the onset of decomposition, it is commonly welded by several methods: butt fusion, socket fusion, electrofusion, bead and crevice free, hot gas welding, extrusion welding, ultra-sonic welding, and hot lamination. Alternatively, Kynar® PVDF can also be mechanically joined. This ease of fabrication enables multiple piping system joining methods, construction of tanks and vessels, and specialty fluid handling components. In addition, Kynar® PVDF and Kynar Flex® PVDF give the designer the ability to confidently join rigid and flexible fluoropolymers in the same construction.

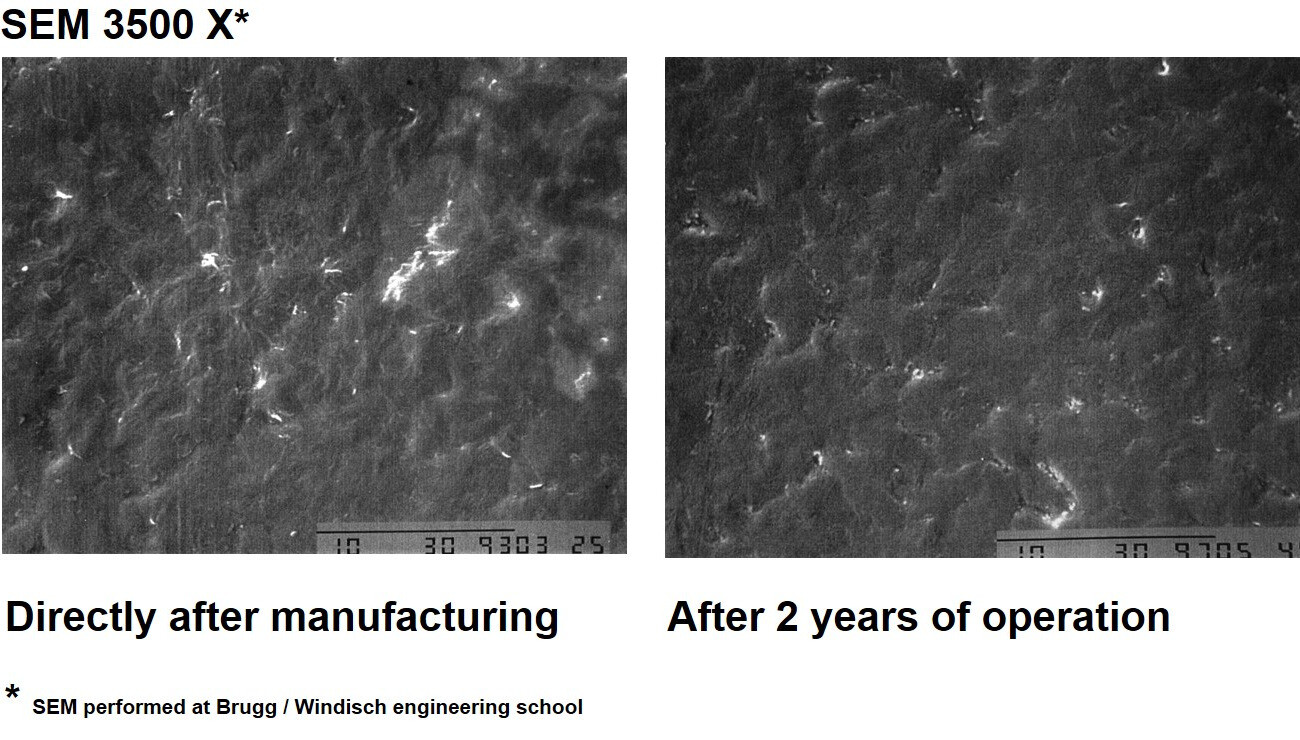

Select grades of Kynar® PVDF are carefully designed with attention to molecular weight distribution and melt flow rate to allow the fabricators who injection mold and extrude to produce parts with very smooth surfaces. In the biopharmaceutical industry this feature is important as it leads to fewer crevices and pores that could harbor the growth of bacteria.

Surface Comparison After Two Years of Operation

Notes: 63 mm pipe (2 1/2"); 1.5m/sec velocity or purified water; sanitized nightly (30 PPM ozone); 2 years of service

Industry Specification Conformity

Select Kynar® PVDF and Kynar Flex® PVDF resins are tested in compliance with Title 21, Code of Federal Regulations, Chapter 1, Part 177.2510 or 177.2600, USP Class VI, NSF 51 & NSF 61, listed in ASME BPE, Kosher certification by the Chicago Rabbinical Council (CRC), and Halal certified.

Sterilization Techniques

Kynar® PVDF resin can be sterilized by most techniques including: steam sterilization, gamma radiation, ethylene oxide (EtO), autoclave, ozone, and other various chemical methods, such as bleach and peroxides.