Nov 4, 2025 - 3 mins

Poolp & Arkema: Where Design Meets Sustainability and Innovation

At the heart of the Formnext 2025 tradeshow—a global stage for additive manufacturing innovation—Poolp and Arkema unveiled a collaboration that expands the boundaries of sustainable design. Their joint creation, a sculptural coffee table named Nomura, is more than a piece of furniture: it is a manifesto for responsible innovation, algorithmic artistry, and the power of partially bio-based materials.

Design as a Dialogue Between Nature and Technology

The project began with a deep conceptual exploration. Poolp, known for its unique approach to robotic 3D printing, envisioned a piece that would embody the fluidity of organic forms while showcasing the capabilities of large-format additive manufacturing. The design process involved advanced 3D modeling techniques, generative algorithms, and a deep dialogue between form and function.

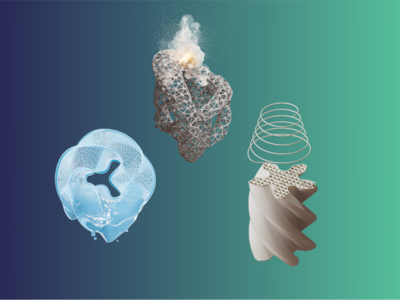

The result is a table whose silhouette evokes the graceful movement of jellyfish—specifically the Nomura jellyfish, a giant species native to Japanese waters. Its undulating curves and translucent presence speak to the fragility and majesty of marine life, while its structural integrity demonstrates the strength of modern bio-based polymers.

Rilsan Clear® Transparent Polyamide: A Partially Bio-Based Material with High Performance and Low Carbon Footprint

Central to this collaboration is Arkema’s Rilsan Clear® Polyamide, a polyamide whose composition is more than 60% derived from castor beans—a renewable, non-food crop that thrives in arid regions. Unlike conventional fully fossil-based materials, Rilsan Clear® transparent polyamide offers a reduced carbon footprint. This makes it an ideal choice for designers and manufacturers seeking to minimize environmental impact without compromising performance.

In addition to its favorable sustainability profile, this transparent material is also a high-performance material designed for durable use. It offers excellent transparency, mechanical strength, chemical resistance and durability, making it suitable for demanding applications in consumer goods such as eyewear and consumer goods. And now, high-end furniture design! Its natural color inspired the final aesthetic of the table and its name, reinforcing the connection between material and meaning.

Through its Virtucycle® program, Arkema is offering a collection service to give a new life to specialty polyamides scraps, including Rilsan Clear® polyamides coming from production waste or end-of-life products. The recycled grades produced from these various sources offer the same high quality and performance, while further reducing the material’s carbon footprint. This reinforces Rilsan Clear® polyamides role not only as a sustainable and high-performance material, but also as a key contributor to circular design.

A Unique Printing Technology: From Granules to Furniture

Poolp’s printing process is different from traditional desktop 3D printing. Instead of using filaments, Poolp’s robotic system prints directly with material pellets, a method that is valued for faster production, reduced waste, and greater scalability. This technique falls under the umbrella of FDM (Fused Deposition Modeling), but Poolp’s approach is adapted for architectural-scale objects and complex geometries.

This pellet-based approach also enables the use of industrial-grade materials like Arkema’s thermoplastics, which are typically available in powder form for Powder Bed Fusion technologies. The result is a seamless integration of material science and digital fabrication, opening new possibilities for designers working at the intersection of sustainability and technology.

Nomura: A Sculptural Piece with a Meaning

The final piece, Nomura, is a coffee table that transcends its function. It’s a sculptural object that invites contemplation, blending contemporary aesthetics with biomimetic inspiration. Its form, reminiscent of jellyfish tentacles and ocean currents, creates a sense of movement and lightness. The translucent quality of the printed material adds depth and nuance, changing with the light and the viewer’s perspective.

Beyond its aesthetic appeal, Nomura tells a story of innovation. It’s a testament to what can be achieved when designers, engineers, and material scientists collaborate with a shared vision. It challenges conventional notions of furniture production and proposes a new model—one that is local, sustainable, and digitally driven.

Made in France: A New Chapter in Design Manufacturing

This project is proudly rooted in France, where both Poolp and Arkema are based. It reflects a growing movement toward local production, circular design, and responsibility. By combining French design sensibility with cutting-edge material expertise, Nomura positions itself as a unique artifact in the landscape of design.

It also demonstrates the potential of additive manufacturing to support decentralized, on-demand production. Instead of relying on global supply chains and mass manufacturing, designers can now create bespoke pieces using locally sourced materials and digital fabrication tools—reducing waste, transportation emissions, and overproduction.

Poolp x Arkema: A Visionary Collaboration

This partnership between Poolp and Arkema exemplifies what is possible when sustainability is placed at the core of innovation. It’s not just about creating beautiful objects—it’s about rethinking the entire lifecycle of design, from material sourcing to end-of-life recycling.

Together, the collaborating teams have created a piece that is algorithmically designed, robotically printed, and materially responsible. Nomura is more than a table—it’s a symbol of a new era in design, where technology and the environment strive in harmony.

See also

Back to all articles- Expertise articles

- White paper

- Case Study