Tubing and Hoses

Kynar® PVDF Flexible Tubing Key Characteristics

- Outstanding flexibility

- Chemical stability

- Clairity

- High purity/ Low extractabales

Benefits:

- Excellent chemical resistance to Fuel C, CE10a, CE50a, CE85a, CM15a, Biodiesel.

- Temperature rating up to 150C continuous

- Low flame and smoke characteristics

- Outstanding permeation compatibility with all hydrocarbons

- High abrasion resistance

- Cold weather impact strength

- Bondable to other materials

Pebax® thermoplastic elastomers' chemical resistance

Pebax® thermoplastic elastomers, in general, possess good resistance to chemicals. They may swell in certain solvents (this tendency is stronger for softer grades). Any application that exposes Pebax® thermoplastic elastomers to chemicals must be considered a special case. It is particularly important to contact Arkema’s technical team, and when possible, carry out tests under real-life conditions. Download the document with details indicating the resistance of Pebax® material grades to common solvents and chemicals.

Pebax® thermoplastic elastomers' chemical resistance sheet

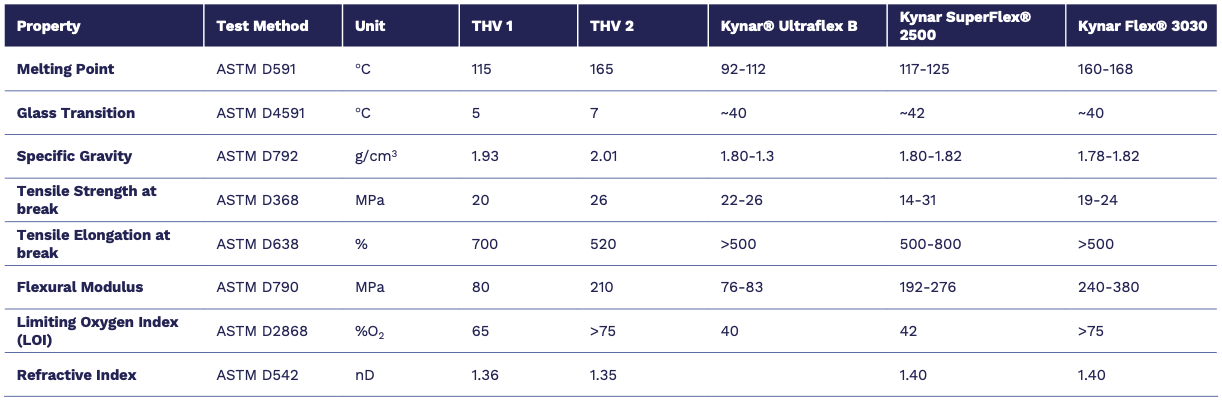

The table above compares some Kynar® PVDF grades to a few THV grades, another commonly used material in fuel permeation barriers for fuels.

Kynar® PVDF Tubing Specifications

| Type | Temperature2 | Pressure1 | Available Diameters |

| Flexible Tubing | up to 107°C (225°F) | vacuum rating up to 2.07Mpa (300 psi) | 1.6 - 152.4 mm (1/16" - 6") |

| Rigid Tubing | up to 121°C (250°F) | vacuum rating up to 1.59 MPa (230 psi) | 3.2 - 324 mm (1/8" - 12-3/4') |

Note1: The above Kynar® PVDF component temperature, pressure and sizing data are compiled from industry data and are for illustrative purposes only. The actual temperature and pressure ratings of your system, as well as its resistance to chemical attack, are dependent on many environmental factors. Higher operating temperatures will reduce the Kynar® PVDF system's maximum operating pressure; higher operating pressures will reduce the system's maximum operating temperature. Higher operating pressures or temperatures may also require increased component wall thickness. Consult your Kynar® PVDF component supplier about your system's operating parameters before purchasing a Kynar® PVDF system.

Note 2: Kynar® PVDF componetns can withstand continuous temperatures as low as -30°C (-22°F) under certain conditions. Please contact your Kynar® PVDF component supplier with specific information about your application to determine the lowest recommended operating temperature of your Kynar® PVDF system.

View and Download Our Tubing and Hoses Brochures!

Kynar® Fluoropolymers Family Presentation