Photovoltaic / Solar

Kynar® PVDF Film

Highly Durable Kynar® PVDF Film

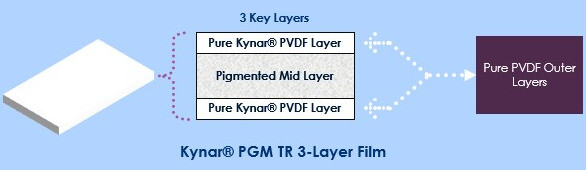

Kynar® PGM TR 3-layer film is made of two outer surface layers of pure Kynar® PVDF sandwiching an inner layer of pigmented fluoropolymer alloy, which gives the characteristic white color.

The pure PVDF outer layer ensures a higher fluorine content than competitive technologies, whose fluoropolymer content is often diluted by pigments and additives:

- Kynar® 3-Layer PGM TR Film: ~59% fluorine in outer layer

- Generic PVDF Films: <50% fluorine

- Typical PVF Films: <41% fluorine

- FEVE Coatings: <<40% fluorine – highly dependent on supplier

This outer layer surface ensures excellent weather resistance, fouling/dirt resistance, extended reflectivity, chemical resistance, and outstanding burn/smoke resistance. Long-term moisture barrier properties are proven to be outstanding.

Kynar® PVDF resins have been used in some of the most challenging material applications in the world for several decades.

Application: Focus on Cable Ties

Outdoor photovoltaic cable management systems require durable cable ties which can withstand a variety of severe environmental conditions. Kynar® PVDF cable ties maintain mechanical integrity at both high and low temperatures, even after continuous exposure to UV radiation. Additionally, the excellent abrasion resistance of Kynar® PVDF makes the cable ties extremely resistant to mechanical damage caused by installation, sand, and debris. Are your standard cable ties failing? Upgrade to Kynar® PVDF cable ties today!

- Read more: Kynar® PVDF Weathering - A New Choice in Cable Ties.

- More on Kynar® Wire & Cable.

- Find Kynar® cable ties at Nile Polymers.

We're Here to Help

We understand your challenges and we’re here to help. No matter where on the planet you are, we’ve got resources to help you. Our global PV Innovation Center is located in France – and we have regional relay technical facilities in USA, China, Korea and Japan. Let us help you today with:

- Co-development

- On-site trials, evaluations

- Characterization, Weather testing

- Lamination testing

View and Download Our Photovoltaic Brochures!

Looking for technical data?