PVDF Separator Coatings: Enhancing Battery Performance

Unmatched performance of PVDF for battery separator coatings

Why select PVDF for battery separator coatings?

Few materials are being developed as the technical requirements are extremely challenging.

Benefits of using PVDF as adhesive layer for battery separator coatings:

- Improved cell manufacturing: adjusted dry adhesion between the separator and electrodes allowing a perfect alignment during manufacturing, better electrolyte wettability vs polyolefin

- Improved cycling performances: excellent wet adhesion preventing cell deformation (no interfacial debonding)

- Improved safety: better thermal dimensional stability, especially when combined with ceramics

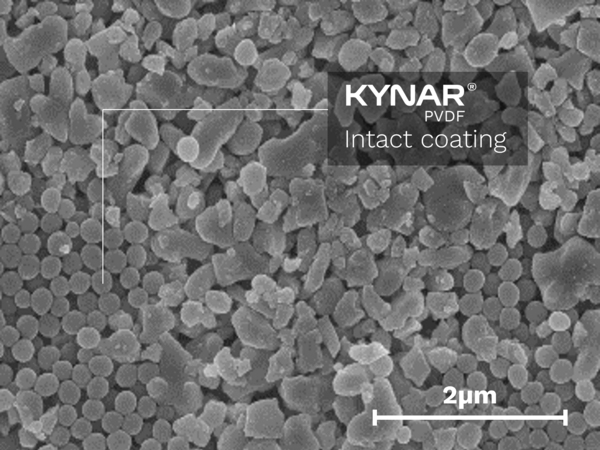

Separator coating with Kynar® PVDF

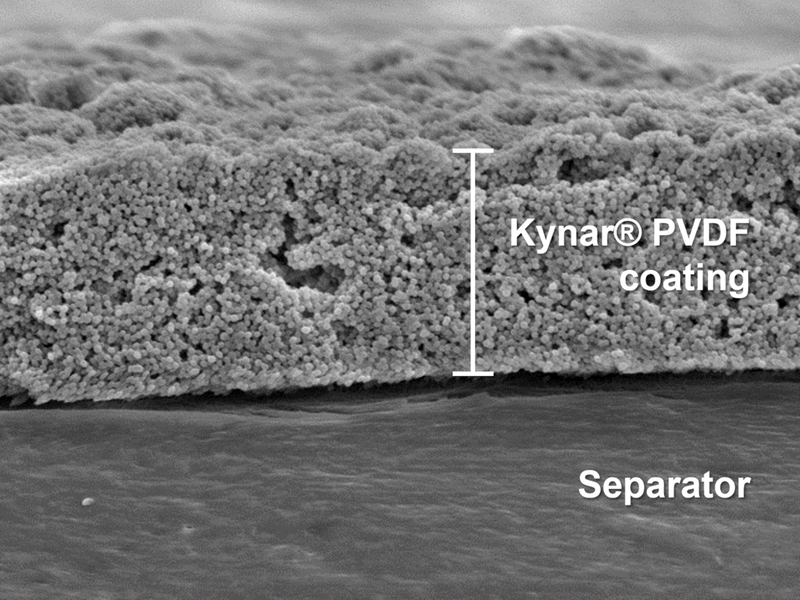

The coating remains porous thanks to the fine particle size of Kynar® PVDF

Today, PVDF stands out as the optimal material for the adhesive layer of separators, combining dry and wet adhesion without compromising resistivity.

The main advantage of PVDF versus most other coating chemistries for adhesive layers is the limited and controlled swelling when exposed to electrolytes. This prevents the undesirable clogging of the separator's pores, maintaining the low resistivity and the overall performance of the cell.

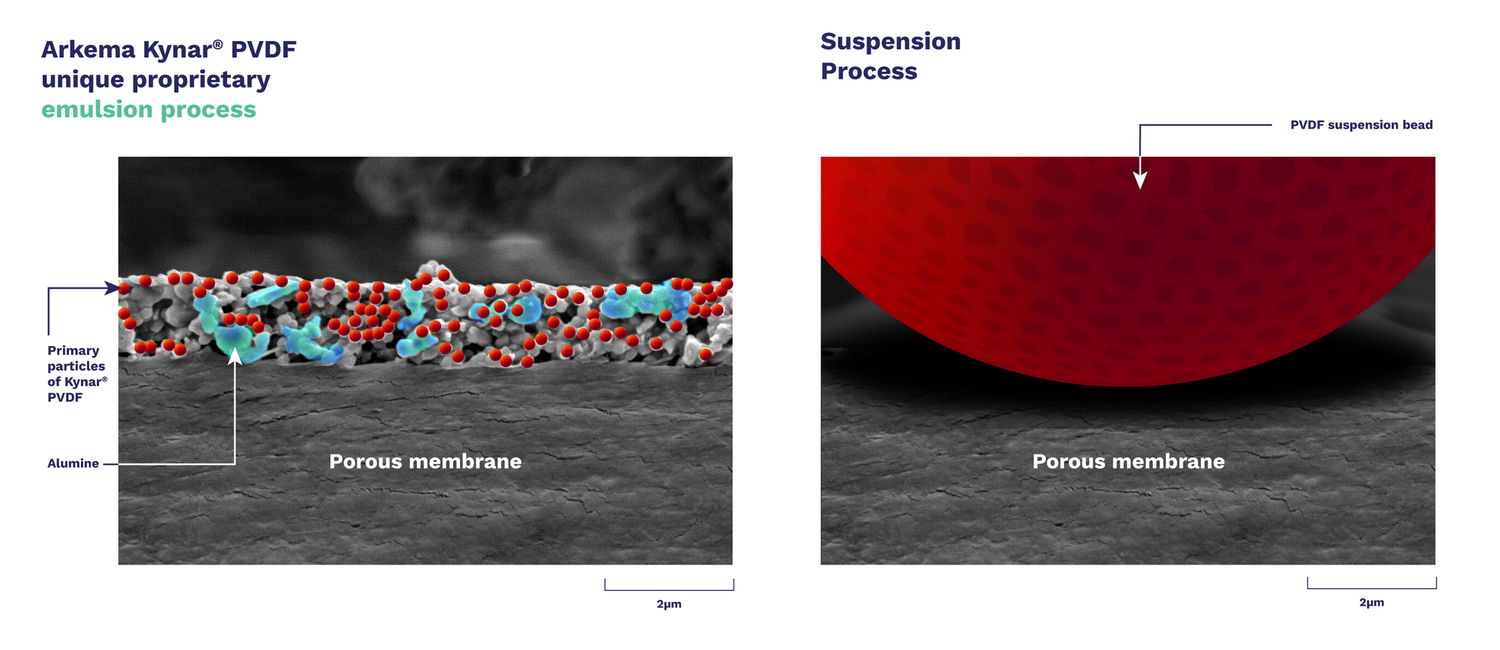

Performance advantages of Emulsion PVDF over Suspension PVDF for battery separator coatings

Not all PVDF polymers are made the same way: Arkema produces its Kynar® PVDF grades by emulsion process and without the use of fluorosurfactants.

Suspension PVDF can only be used in old-fashioned solvent born processes. On the contrary, thanks to highly controlled primary and secondary particle size, Emulsion PVDF is the only solution for waterborne technologies.

A unique offering and expertise in waterborne coating technologies

Thanks to its emulsion process, Arkema is able to offer Kynar® PVDF solutions in both Latex and Powder forms.

Kynar® PVDF ranges for battery separator coatings provide great electrode adhesion in both wet & dry conditions, high voltage stability, high dimensional stability, controlled crystallinity and ceramic compatibility.

KYNAR® PVDF AQUEOUS LATEX

Aqueous media in which the primary PVDF particles remain dispersed. Typically preferred in microgravure processes.

Kynar® PVDF aqueous latex is a high-performance, water-based medium in which primary PVDF particles remain uniformly dispersed. This makes it particularly suitable for microgravure processes used in the manufacturing of battery separators. As a critical component in lithium-ion batteries, Kynar® PVDF latex enables the creation of uniform, durable coatings that enhance separator functionality by providing excellent chemical resistance, mechanical strength, and thermal stability.

With Arkema’s deep-rooted expertise in water-based coatings, Kynar® PVDF latexes are engineered to deliver optimal performance in separator applications. They ensure superior adhesion, controlled porosity, and exceptional wettability for enhanced electrolyte compatibility.

KYNAR® PVDF POWDER

Powder to be redispersed in an aqueous phase. Typically preferred in microgravure and spray coating processes.

Kynar® PVDF powder is a specialized material designed for redispersion in aqueous systems, widely preferred in microgravure and spray coating processes for battery separator production. Derived from a high-purity latex through a precise drying process, the powder forms secondary particles with a controlled median diameter of less than 10 µm. These secondary particles can be easily redispersed in water, allowing the creation of uniform coatings with the desired thickness and consistency.

In the context of lithium-ion battery separators, Kynar® PVDF powder plays a crucial role in delivering superior separator performance. Its optimized particle size and dispersion properties enhance separator coating uniformity, contributing to improved ionic conductivity, mechanical integrity, and resistance to chemical degradation. Arkema’s advanced particle engineering ensures consistent, reliable performance, meeting the stringent demands of modern battery applications.

Recognizing that each battery manufacturer uses a unique electrolyte formulation, the demand for customized solutions requires copolymers with precise swelling characteristics. In addition to offering both powders and latexes, Arkema provides the widest portfolio of KynarFlex® copolymers to fulfill the various technical needs of customers.

FOCUS ON: KYNAR® PVDF POWDERS

Powder redispersion is typically used in spray coating or microgravure processes. The Kynar® PVDF powder is dispersed into an aqueous media followed by a milling step to achieve the desired particle size. The slurry is then post formulated.

It is possible to adjust the particle size distribution from 7 to 1 µm by varying the grinding parameters (grinding time, bead size, filling ratio, rpm, etc.).

A unique R&D expertise in battery materials

Center of Excellence for Batteries

Arkema's Christian Collette Center of Excellence for Batteries (located in Pierre-Benite, France) is dedicated to new development programs in line with next-generation battery technologies. Equipped with state-of-the-art equipment, the R&D teams have advanced coating, assembly and testing capabilities to support your battery separator developments.

Contact us for questions on our technologies or technical assistance: