Chemical Process Industry (CPI)

Kynar® PVDF and Kepstan® PEKK solutions are specified for some of the most demanding chemical environments in the world.

For chemical processing applications requiring high temperature resistance, tremendous chemical resistance, and exceptional barrier properties, Kepstan® PEKK and Kynar® PVDF resins offer truly extreme performance.Such applications often include valves, barrier films, protective coatings, and chemically resistant labels.

Kynar® PVDF - a Standout Fluoropolymer for CPI

When it comes to the most demanding applications in the chemical process industry, fluoropolymers are famous for their tremendous chemical resistance and overall durability. Kynar® PVDF has the best balance of mechanical properties and melt processability among all the fluoropolymers. Rigid, flexible and highly flexible grades are available.

Chemical Resistance Testing (6 Month Outdoor Exposure)

|

Chemical Reagent |

Kynar Flex® 2800 |

Kynar Flex® 2850 |

Kynar® 740/720 |

|---|---|---|---|

|

Tensile Strength at Yield Control Specifications ASTMD638 |

(2900 – 3900) psi (20-27) MPa |

(4500-5500) psi (31-38) MPa |

(6000-8000) psi (41-55) MPa |

|

Nitric Acid (71%) |

3100 psi |

5000 psi |

6400 psi |

|

Hydrofluoric Acid (49%) |

3100 psi |

5200 psi |

7000 psi |

|

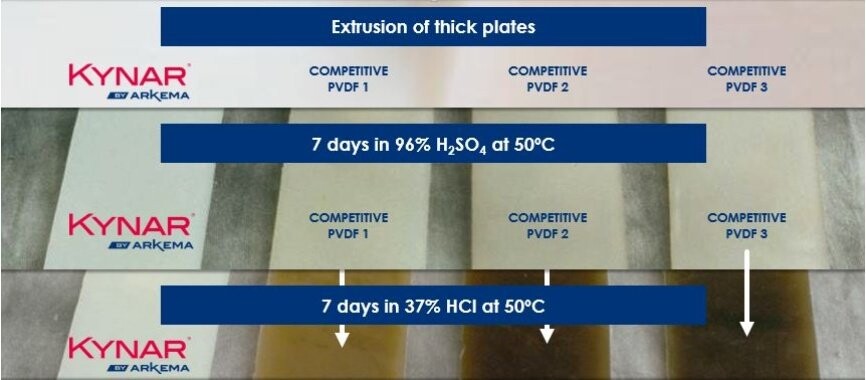

Sulfuric Acid (96%) |

3100 psi |

4900 psi |

6600 psi |

|

Hydrochloric Acid Shielded Sample (37%) |

3200 psi |

Not Tested |

6800 psi |

|

Acetic Acid (50%) |

3300 psi |

5000 psi |

6600 psi |

|

Sodium Hypochlorite (5%) |

3100 psi |

4800 psi |

6500 psi |

|

Liquid Bromine |

3100 psi |

4800 psi |

6500 psi |

|

Iodine (10%) |

3200 psi |

4800 psi |

6600 psi |

|

Acetone (10%) |

3400 psi |

5100 psi |

6400 psi |

|

Methylene Chloride |

3000 psi |

4300 psi |

6200 psi |

|

Ethylene Glycol |

3400 psi |

5000 psi |

6900 psi |

|

Distilled Water |

3200 psi |

5000 psi |

6800 psi |

Note: PSI = MPa/145

For More Data:

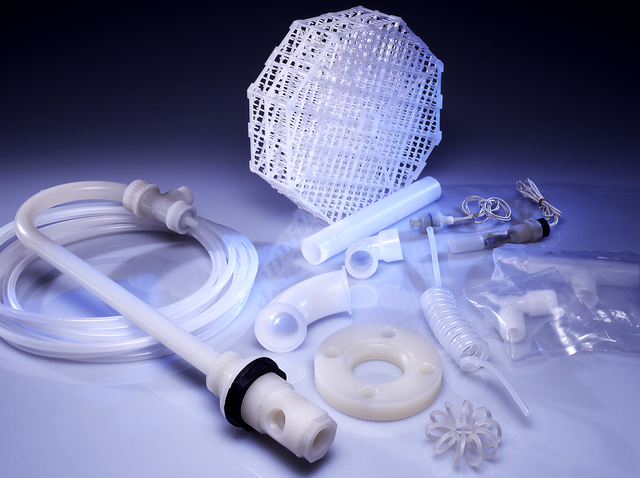

Typical Applications in the Chemical Process industry for Kynar® PVDF Resin

Design engineers all over the world know it by name - Kynar® PVDF. The brand is synonymous with quality, purity and performance.

Typical applications include stock shapes (machinable rods and sheets), tubing, molding, piping, tower packing, filters and compounds for many of the following.

- Pulp and paper processing - resistant to common bleaching agents

- Metal preparation - resistant to high temperature acids

- Petrochemicals - resistant to alkylation acids and hydrocarbon mixtures

- Food and beverage - FDA listing, resistant to steam cleaning, acidic foods, and harsh chemical sterilization techniques like peracetic acid (PAA) and bleach

- Waste water treatment - resistant to chemical mixtures, outdoor and UV exposure, and halogenated cleaning agents

- Pesticides - resistant to halogenated solvents; low permeation

- General chemical processing - resistant to a wide range of pH exposures pH<1 to 13.5

- Semi-conductor manufacture - very high purity water, resistant to acids and ozone

- Pharmaceutical / Biotech - resistant to ozone and steam sterilization, FDA compliant, resistant to a wide array of acids

- Plenum pipe - resistant to acid waste drainage, ASTM E84 compliant

- Nuclear waste processing - resistant to repeated radiation exposure and hot acid washes

- Chemically resistant powder coatings

Suggested Applications for Kynar® PVDF Resin in the Chemical Process Industry

The high heat resistance, low permeability and high mechanical strength of Kynar® PVDF makes it a strong candidate for the production, storage and transfer of highly corrosive fluids.

Stock Shapes: Kynar® 740, Kynar®1000HD, Kynar Flex® 2850, and Kynar Flex® 2800.

Molding: Kynar® 720, Kynar® 9000HD, and select Kynar Flex® grades.

Plenum Pipe: Kynar® 740-02 ,Kynar® 1000HD and Kynar Flex® 2850-02.

Rigid Pipe: Kynar® 740, Kynar® 740 Red, and Kynar® 1000HD.

Flexible Tubing: Kynar Flex® resins.

*More grades of Kynar® PVDF are available. Contact your local Kynar® PVDF rep to make the right grade selection for your application.

- Kynar® 1000HD Datasheet US/SI

- Kynar® 9000HD Datasheet US/SI

- Kynar® 740 Datasheet US/SI

- Kynar® 720 Datasheet US/SI

- Kynar Flex® 2850 US/SI

- Kynar Flex® 2800 Datasheet US/SI

- Kynar Flex® 2750 US/SI

- Kynar Superflex® 2500 Datasheet US/SI

High Whiteness Retention in Prolonged Chemical Exposure

Kynar® 1000 series: High whiteness and Whiteness retention

Kynar® 700 series: Flagship product line with excellent performance balance

Kynar® UHM: Glass filled for higher stiffness (modulus)

Kynar® Flex series: Flexible copolymers with a wide range of flexural modulus properties

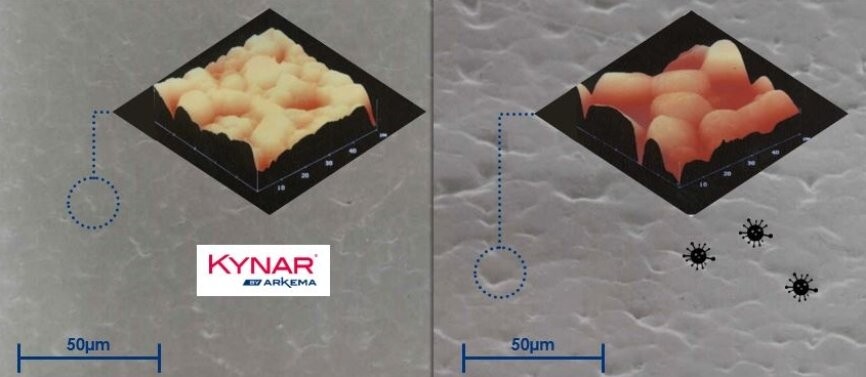

Smoother Surface = Less Build-Up

Kynar® emulsion process PVDF generally exhibits a smooth surface finish with fewer nucleation voids for entrapment of contaminants. This equates to less bacterial build-up, and a higher purity polymer.