Kynar® PVDF Provides High Purity, Chemically Resistant Solutions for the Semiconductor Industry

With a proven history in the semiconductor industry, Kynar® PVDF resins have been used for their high purity and chemical resistance for piping, wet benches, and other equipment within chip making facilities.

High Purity Semiconductor Applications

- High Purity Piping - Easy to join and weld especially infrared welding

- Wet Benches - high purity, high chemical resistance for washing and etching

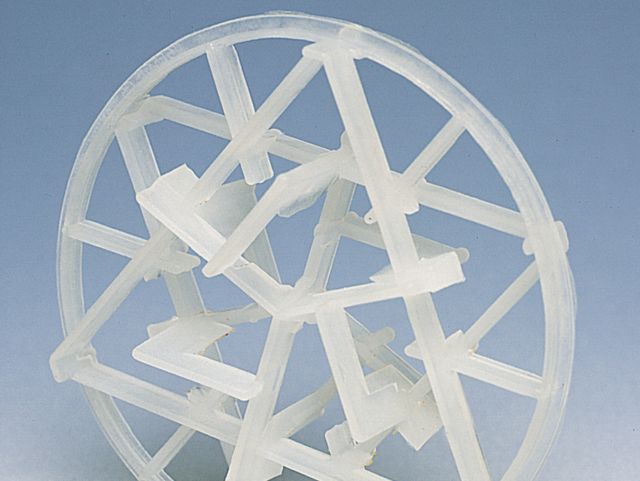

- Tower Packing - for use in acid scrubbers and distillation columns

- Tanks - Avaialbe in solid plastic, lined metal, and dual laminate constructions for chemical storage

- Pumps & Valves - high purity and mechanical strength for control systems in your process stream

- Rods & Sheets for customized parts - easily machined and welded components tailored to your process

Severe Service Conditions Commonly Handled by Kynar® PVDF

- Hot Acids include hydrofluoric acid, sulfuric acid, and hydrochloric acid

- 18 MegaOhm Deoinized (DI) water

Why Kynar® PVDF for Semiconductor?

- High Purity – Strict regulations on low leachables and extractables govern the semiconductor industry. Kynar® PVDF resins continue to meet these requirements

- FM 4910– The excellent flame and smoke properties of Kynar® PVDF make it an approved material for use in semiconductor clean rooms

- SEMI F57 Compliance - Specification for Polymer Materials and Components Used in Ultrapure Water and Liquid Chemical Distribution Systems

- Easy Weldability – Kynar® PVDF resins are easily weldable. In piping, Kynar® PVDF can be joined via infrared methods, ensuring a reliable connection method while maintaining purity standards

- Chemically Resistant – Common chemicals handled by Kynar® resins include hot acids and deionized water.